BorgWarner — a developer of mobility technologies such as electric motors, batteries and thermal management solutions — recently signed agreements with two major vehicle OEMs to supply components for their electric vehicles.

The company will supply its High-Voltage Hairpin (HVH) eMotors to an automotive OEM in China and its high-voltage eFan system to a global commercial vehicle OEM for use in heavy-duty electric trucks.

Continued growth of electrification in the heavy-duty trucking and passenger car markets, among other mobile industries, is driving an increased need for electric motors, fans and other components necessary to help power these vehicles. As such, BorgWarner, like many companies, is focusing much of its business on developing the power transmission products needed for this growing sector.

READ MORE: The Impacts of Electrification on Fluid Power Systems

Compact and Efficient eMotors

BorgWarner's HVH eMotors will be used within the automotive OEM's Dedicated Hybrid Transmission (DHT) and Range Extended Electric Vehicle (REEV). According to Dr. Stefan Demmerle, President and General Manager of BorgWarner PowerDrive Systems, this motor is well suited for the application due to its inclusion of a high-performance electric generator.

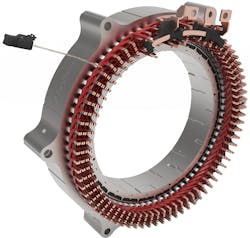

The HVH eMotors feature an optimized conductor-winding structure which shortens the motors, providing a more compact design. This benefits installation in electric vehicles where space is often at a premium and additional weight from larger components can negatively impact efficiency, and thus energy use. BorgWarner says this design also helps to improve efficiency during major driving cycles, with peak efficiencies over 95% possible.

These electric motors are available as a fully housed motor or rotor/stator assembly, offering design flexibility for OEMs. In addition, BorgWarner designed the motors to use fewer heavy rare earth elements which not only reduces the cost of the motor but also the environmental impact of producing them.

Noise, vibration and harshness (NVH) levels for the motors were reduced as well by optimizing the auxiliary slot, aiding with quieter vehicle operation.

eFan Benefits Cooling for Electric Vehicles

BorgWarner's eFan R10 system will be used in heavy-duty battery-electric trucks set to be deployed in both the European and North American markets. According to the company, this is the first order for the system in the North American market as well as its use in the high-voltage, low-power segment globally.

READ MORE: How to Safely Work with High-Voltage Systems

The eFan R10 consists of a fan, e-motor and integrated high-voltage inverter, offering OEMs a complete cooling system to ensure optimized performance of electric powertrain components. Features of the eFan R10 system include the ability to provide up to 10 kW of power and 40 Nm torque as well as an operating temperature ranges from -40 to 80 C.

In addition, the eFan system has a wide operating voltage range of 600-850V without derating which enables compatibility with a variety of high-voltage commercial vehicle electrical systems in the marketplace. The fan's electric motor and power electronics are liquid cooled which provides a robust and compact design as well as reliability to ensure a long lifespan.

The fan system is suitable for both battery-electric vehicles and fuel cell electric vehicles, aiding OEMs with whichever diesel alternative they choose.