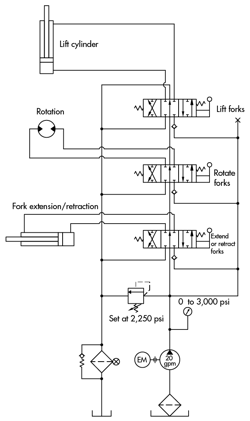

A lumber company had an older yard stacker machine that they wanted to put back into service. It had been out of service and parked due to a problem with its boom sometimes dropping. The boom lift cylinder would drop when the operator also rotated the forks at the same time to align the 4×8 and 4×12 sheets of plywood and plasterboard when placing them on top of other stacks.

I looked at the problem and noticed the operators would lift and rotate at the same time when the problem happened. If they only ran one function, the problem would not occur. All the other trucks worked well running both at the same time and expedited the unloading of the supply trucks. I told them they could use the truck but not to rotate while they were lifting. This sounds well and good, but the operators were accustomed to using the other trucks, so the operators sometimes ran lift and rotation at the same time out of habit. As a result, the problem still occurred.

The circuit shown seems to be how the hydraulic system was designed. Any idea about how to solve the problem?

Find the Solution

Think you know the answer to this month’s problem?

Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by June 1, 2015, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Problem:

Elephant House Door Open on Their Own

The gate problem grew out of expansions to the elephant housing facility. Several gates were being used at the same time, and because the tubing was elevated, air entering the system during hydraulic filter element changes caused pressure spikes in the tank line. The pressure spike would show up in several cylinder ports because the A and B lines were directly drained to tank in the neutral position.

Because all the valves were D03 sub-plate mounted design, technicians felt the easiest solution was to install tank line check valve modules under all the directional valves.