Government regulations are a key driver for implementation of many technologies, such as safety systems on vehicles and the current transition to electrification. Ensuring these regulations are met can therefore impact various industry design needs, including those for fluid power and related motion systems.

Ever stricter emissions regulations, for instance, have increased use of battery-electric power systems in cars, trucks and off-highway equipment. As such, hydraulics and pneumatics component suppliers are having to develop solutions which better work with the new requirements brought about by these electric vehicles.

In its recently released emerging trends report, the Society of Tribologists and Lubrication Engineers (STLE) cited government regulations as a top trend which will impact the industry in the coming years. Besides the technology changes necessitated by the push toward electrification, there are regulations – or proposed ones – aiming to limit use of some chemicals that have previously been used in lubricants. This is bringing about the need to consider new materials and formulas.

New regulations will continue to be put in place to help create safer and cleaner environments, bringing with them various design needs and possibly even opportunities for advancements that might not otherwise have been considered.

Transitioning Heavy Trucks to Zero Emissions

Efforts to reduce emissions from medium- and heavy-duty trucks — an important customer market for the fluid power industry — are ongoing due to the amount produced by these vehicles. Regulations in Europe, China and the U.S., among others, have helped to reduce emissions from this sector already while also being an impetus for the growth of electrification in trucking and other industries.

New regulations continue to be put on the books to curb emissions even further, many of which aim to create a gradual progression toward the ultimate goal of zero emissions. The California Air Resources Board (CARB) is known for setting some particularly stringent emissions regulations in the U.S. In June 2020, it adopted a rule requiring manufacturers to transition from diesel-powered trucks and vans to electric zero-emission alternatives starting in 2024.

Known as the Advanced Clean Truck regulation, the rule aims to encourage the development and use of available technologies as well as those coming in the future to mitigate emissions produced by the transport sector.

This was followed in April 2023 by the Advanced Clean Fleets rule requiring a phased-in transition to zero-emissions medium- and heavy-duty vehicles. The goal is for all trucks traveling California roadways to do using zero-emissions technology by 2045. Also included in the rule is a stipulation to end sales of combustion engine powered trucks in the state by 2036.

Achieving these goals will require a lot of engineering effort from OEMs, component suppliers and other entities. While battery-electric vehicles are available in the heavy transport sector, there is still a lot of work to do in order to extend their range capabilities as well as expand charging infrastructure. Use of hydrogen fuel cells and other diesel alternatives also present potential options, but again require more engineering efforts to bring them to reality.

For those in the fluid power sector, implementation of battery-electric systems in trucking and other sectors is already bringing new technology requirements to market, such as the need for hydraulic systems to operate more efficiently. As these and other alternatives gain in use, so too will additional development requirements.

READ MORE: The Impacts of Electrification on Fluid Power Systems

Understanding the large undertaking this will be, CARB recently announced formation of the Clean Truck Partnership. Several leading truck manufacturers as well as the Truck and Engine Manufacturers Association have joined the partnership as a commitment to meeting these new CARB rules while also collaborating with the government organization to ensure lead times for meeting the rules are feasible.

This will help to ensure the necessary technologies are developed an implemented but in a manner which is feasible for manufacturers and the market.

Read more about the partnership from FleetOwner, an Endeavor Business Media partner site.

Improving Pedestrian Safety with Automated Braking

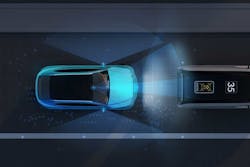

In May 2023, the U.S. Department of Transportation's (DOT) National Highway Traffic Safety Administration (NHTSA) proposed a rule requiring automatic emergency braking (AEB) and pedestrian AEB systems on passenger cars and light trucks. The goal is to of course help improve the safety of roadways and pedestrians.

Advanced safety systems like this not only help to save lives but are also key components of future autonomous systems and vehicles which will require several aspects to be automated, including braking.

Through use of sensors and other technologies, AEB systems automatically apply a vehicle's brakes when a pedestrian or other vehicle is detected if a driver does not do so to avoid a collision from occurring. As hydraulics are an important part of brake systems in passenger cars, they will need to work with the AEB to ensure it achieves the desired results of stopping a vehicle.

Greater integration of electronics with hydraulics, which is already taking place, will aid with the integration of AEB systems and their ability to communicate with the braking system. In addition to enabling communication between systems, the presence of more electronics in hydraulics is helping to bring about more precision and control which also benefit their use with automated systems such as AEB.

READ MORE: Increased Demand for Electronic Controls Driving Hydraulic System Designs

If NHTSA's rule is adopted, vehicles in the U.S. with a gross vehicle weight rating of 10,000 lbs. or less will be required to have the AEB technology within 3 years of the publication of the final rule.

Although meeting government regulations can cause design challenges, the need to figure out new solutions is also helping to bring a little life into industries like fluid power which are often not thought of as being as exciting or on top of technology trends. While those of us who are in or cover the industry know otherwise, as many have said in recent years, it's an exciting time for the industry with all of the advancements taking place and design challenges to solve.

We want to hear from you!

What regulations are having the biggest impacts on your design decisions? What challenges are you facing because of these regulations? Are there any new regulations you see coming down the pipeline?

Let us know by reaching out to us directly via email [email protected] or on social media.

Twitter: @TechnlgyEditor or @PowerMotionTech

LinkedIn: @PowerMotionTech