Gefran Inc. is introducing its KM industrial pressure transducer to the North American market. The transducer can be used in a range of mobile and industrial hydraulic applications.

Features of the KM pressure transducer include:

- pressure range options up to 14,500 psi (1,000 bar)

- five electrical connector styles

- stainless steel housing

- shock and vibration resistant.

Compact Yet Durable Design

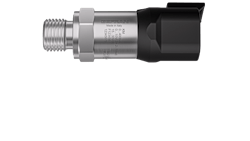

Gefran designed the KM industrial pressure transducers to be smaller than its existing line of KH transducers. The KM series features a stainless steel housing measuring under 52 mm in length with a hex diameter of 19 mm wide. It also weighs less than 2 oz. These size and weight savings help to ease integration, particularly in space-constrained applications.

Though compact in size, the KM transducer offers improved operational and safety features. According to Gefran, it has the highest environmental rating at IP69K, a PL’d certification for mechanics, and a cULus certification to meet U.S. and Canadian requirements.

"Our OEM customers are focused on size and weight reductions to help increase equipment fuel efficiency, as well as increasing operator safety in ultra high-pressure applications. The KM is designed to help address these concerns and provide a high-quality solution that OEMs and engineers can rely on," said Ron Akers, Gefran’s business development manager, in the company's press release announcing the transducer's introduction.

The transducer has an increased voltage supply range as well from 8-32V and electromagnetic (EMC) stability to withstand up to 100 V/m interference. In addition, it features shock resistance up to 100g and vibration resistance up to 20g to ensure longevity in a range of harsh applications.

Gefran's transducer can be used in various high-pressure mobile and industrial fluid power applications, including hydraulic tools, such as torque wrenches, hydraulic accumulators, and clamping and jacking systems.

Hydraulic Pressure Monitoring Aids Efficiency

The KM industrial pressure transducer provides quick and reliable measurements. Aiding this is the transducer's linearity best fit straight line pressure accuracy of ±0.15% full scale, an ambient temperature range of -40 to 125 C, and SIL2 certification for electronics.

Akers explained the KM hydraulic pressure transducer is capable of communicating low- and high-pressure limits to a machine controller, enabling better determination of "when to use energy stored in the hydraulic accumulator at high pressure. Then the controller can use the low-pressure reading of the transducer to direct a valve in the circuit to divert oil flow to recharge the accumulator."

READ MORE: Controlling Hydraulic Pressure

This helps OEMs to reduce energy use, a greater concern for both mobile and industrial applications as machine owners look to be more efficient and sustainable in their operations.

The transducer can be customized to meet specific customer applications if needed, with various documentation and packaging options possible in addition to the standard output signals, process connectors and pinpoints.