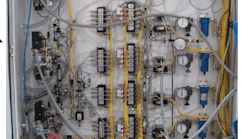

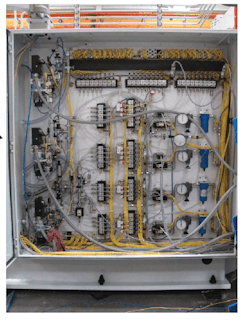

Leak testing is regularly employed in production and assembly plants on most pressure-containing vessels because it ensures product quality and integrity. The valve used in testing should be reliably leak-proof itself. If it is not, testing efforts are a waste of time. That is why Ross Controls, Troy, Mich., developed its high-flow, bubble-tight Dale Series LT, CX and LX valves and manifolds. They feature a poppet design and high sealing capabilities.

The Dale series valves come in standard pressure ranges from high vacuum to 250 psi. They are pressure independent, so pressure or vacuum can be applied to any port at any time. Low wattage coils hold down energy consumption and help prevent heat buildup. These bi-directional valves are offered with compact manifolds that eliminate piping (and potential leak paths) and spacing between valves, for simplified installation.

In channel select applications, users are able to test multiple parts at a time or multiple chambers in a single part. With bypass fill and exhaust applications, the Dale Series valves’ high-flow capability can improve cycle time and be used as an exhaust valve, to prevent contamination to other units.

For more information, visit Ross Controls.