Swimming has long been recognized as an almost ideal form of exercise. Weight-free exercise in an aquatic environment provides a superior cardiovascular workout without muscle or joint stress due to impact with the ground. Most people find swimming enjoyable and exhilarating, but few have space for a full-size lap pool — indoors so the weather won’t interfere with their exercise program.

Endless Pools, Inc. of Aston, Pa., has a solution to the space problem. Their modular pools’ exterior dimensions are 8-ft wide 3 15-ft long 3 312-ft high. The swimming area is 7 3 14 ft. All components fit through a 24-in. doorway, so the 2500-gal pool can be assembled in existing ground-floor rooms or outdoors on a deck or patio.

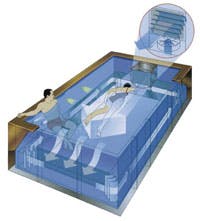

So how do you swim for exercise in such a modest-sized pool? The patented Endless Pools design produces a broad, deep, non-turbulent water current down the center of the pool. Simply relax and swim in place, just fast enough to keep pace with the water flow. Swimming against a current is more fun, and any time you want to stop, you just stand up in the waist-deep water. To move out of the current or adjust its speed with the poolside valve requires only a step aside into calm water.

Perhaps surprisingly, a hydraulic propulsion assembly generates the current. A hydraulic motor, underwater inside a protective stainlesssteel housing at the end of the pool, drives a 16- in. propeller. The propeller moves water at flows up to 5000 gpm through a grill that smooths and straightens the current. The water travels down the center of the pool, from front to rear, at a speed selected by the swimmer. The current then enters another grill in the rear bench. From there it circulates back to the propulsion-assembly chamber through corner turning-vane arrays and inside the two underwater side benches. The benches serve as return channels and provide perimeter seating.

The power unit that supplies the hydraulic motor can be placed as far as 75 ft away from the pool. It has of a 5-hp, 220-V/23-A, single-phase electric motor driving a 6-gpm, 1500-psi pump. The system uses a biodegradable vegetable- oil hydraulic fluid, which, if spilled, poses no serious threat to the environment. From the power unit, plastic pressure and return hoses (from Parker Hannifin’s Parflex Div.) connect to the propulsion assembly with stainless- steel fittings. The hoses damp noise and are electrically non-conductive. In fact, there are no electrical connections near the pool — an important safety feature.

Danfoss Fluid Power, Racine, Wis., supplies the OMP50C low-speed/hightorque motor. A rotary bypass valve regulates the motor’s speed (and thus the propeller’s). Opening or closing the valve increases or decreases the rate of water flow. In industrial hydraulic circuits, heat buildup might be a concern when using a bypass valve to control a motor. In the Endless Pool installation, heat is dissipated through the hoses and the hydraulic motor — all of which are submerged in the pool.

The 2.96-cir motor has an industrial rating of 2500-psi continuous, 3300-psi peak pressure. Maximum continuous speed is 1250 rpm. This drive application does not challenge the motor, but life under chlorinated water does, so Endless Pools recommends that it be changed every three to five years.