Fluid power often is the first choice whenever a predictable amount of force must be exerted, where the compressibility of the fluid medium can be used to avoid damage to the test specimen, or where heavy loads must be held or moved as part of the testing process. For example, a hydraulic cylinder in a building truss tester can apply loads to simulate harsh environmental conditions, such as wind and snow loading. A vehicle leaf spring tester, a testing machine for medical prostheses, and a gas cylinder pressure tester all use fluid power to apply the same usage patterns over a period of hours or days that the items under test would normally encounter over a lifetime.

Closed-loop position and force control

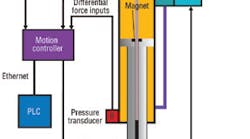

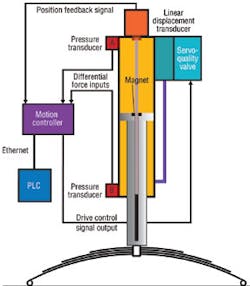

Motion control in testing applications, of course, requires precise position control, speed control, or both. But to gain the full potential also requires the motion controller to implement closed-loop control of the pressure or force being applied to the test specimen. Simply controlling the position of a cylinder is not adequate because doing so cannot detect subtle changes in the physical properties of the text specimen unless the force required to flex it can be monitored. In a fluid power system, the force applied by a cylinder can be determined by monitoring the difference between pressures on either side of its piston.Figure 1 shows a diagram of a leaf spring tester designed to repeatedly flex the spring while measuring the force required to displace the spring leaves. A motion controller monitors pressure from transducers to measure force, and a magnetostrictive linear displacement transducer (LDT) measures position of the cylinder.

Position control may be used in a typical test operation to put the actuator in approximately the right position for applying a controlled amount of force. Engineers should look for an electronic motion controller that’s easy to program and can smoothly transition between controlling position and controlling pressure.

The motion controller in Figure 1 drives the hydraulic cylinder by sending analog signals to a proportional or servovalve capable of making precise adjustments (sinusoidal or other waveforms) to pressure for controlling the cylinder’s force or position. An accumulator (for simplicity, not represented in Figure 1) stores hydraulic pressure to ensure that consistent system supply pressure is available to operate the servovalve during spring compression cycles.

Programming the motion

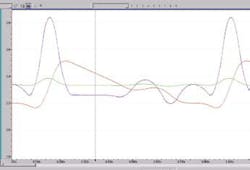

As mentioned, non-destructive testing programs often involve applying repetitive stress cycles on the test specimen. A motion controller that supports direct execution of cyclic motion operations makes it quick and easy to set up testing profiles. Figure 2 shows plots of repetitive motion sequences that can be applied to a test specimen.Figure 2 illustrates that cyclic doesn’t always mean simple. The proper motion controller operations can simulate some very complex realworld motion scenarios. Now let’s examine some real cyclic testing applications that are benefiting from fluid power systems under closed-loop control.

Leaf spring testing

When a systems approach was taken to develop the test system, new capabilities were enabled, such external control modules to interrogate the system and to analyze process data. For example, leaf spring manufacturer Rockwell American, of Seagoville, Texas, used data on the force being applied to springs under test to identify how structural parameters in the steel change over time. This capability was useful in helping Rockwell American diagnose and document a recent material quality problem. They also realized significant savings in setup time whenshifting from one spring type to another. In Rockwell American’s spring tester, Figure 3, an RMC100 controller from Delta Computer Systems accurately follows operator selectable, internally- generated target force profiles through a human-machine interface. Each spring movement is controlled by continually adjusting drive output to the hydraulic valve 1000 times a second. Simultaneously, minimum and maximum spring deflections are monitored in real time during the force cycling and compared to allowable limits to determine any change in the properties of the spring. These limits are found for each spring when the motion controller is commanded to enter force control, which is initiated by an operator through a touch screen.

At the beginning of the testing cycle, the system compresses the spring to minimum and maximum force set points while recording and storing the corresponding minimum and maximum spring deflections. If the position of the hydraulic cylinder exceeds operator specified tolerances during the continuous force control cycle testing, the spring properties may be changing, the spring may be ready to break, or one leaf in the spring may have already broken. If this condition occurs, the motion controller’s continuous monitoring of position tolerances during force cycling will lead to an automatic system shut down. Because of these controls, the machine can run continuously with minimal supervision. The new machine is also capable of capturing and plotting test data for post-test diagnostics and record keeping.

Prosthetics tester uses pneumatics

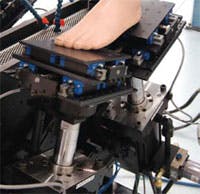

A prosthetics manufacturer has the requirement, imposed by the International Standards Organization (ISO), for testing elastic ankle joints to ensure that they can flex under realistic conditions through at least two million cycles. A key to realistic testing is to ensure that the displacement of the joint is within a certain limit when a particular force is applied during each cycle.Orion Test Systems & Engineering Inc., of Lake Orion, Mich., manufactures such a tester. The test system uses two pneumatic cylinders controlled by a Delta RMC75 two-axis motion controller. One cylinder is positioned to press on the heel and the other to push on the toe of an artificial foot, Figure 4. Like the previous example, a magnetostrictive LDT uses a magnet affixed to each piston to measure the position of each cylinder. However, unlike the leaf spring tester, this system does not measure differential pressure in the cylinder. Instead, a load cell affixed to each cylinder measures the force applied.

As the test system cycles, the cylinders alternate their motion to flex the joint. For each cycle, the motion controller increases the force being applied on each cylinder until it reaches a predetermined set point. It then measures the amount of deflection of the joint to ensure that less than maximum force has been applied.

Because data on the amount of deflection are collected every cycle (by a PLC that reads registers in the motion controller), the tester can measure the onset of fatigue before a catastrophic failure occurs. The motion controller is capable of cycling the tester two to three times per second — roughly twice the rate from the previous controller used by the prosthetics company, which doubles throughput of the testing facility.

Pneumatics was chosen for this tester rather than hydraulics in order to keep the weight of the test system as low as possible. However, because air is more compressible than oil, system tuning became a challenge. The real-time motion plotting and tuning tools provided with the Delta motion controller made tuning the system for optimal performance easier.

Motion controller produces precise pressure cycling

Catalina Cylinder Corp., Garden Grove, Calif., a leading producer of aluminum cylinders used to transport oxygen, carbon dioxide, and other gases, poses another innovative test system application for hydraulics. Catalina’s engineer, John Kishel, got the idea using one of Delta’s RMC motion controllers for closed-loop control of a hydraulic cylinder to pressurize the gas cylinders under test. The apparatus Kishel designed is shown Figure 5.The system uses a hydraulic cylinder acting as a pump. The rod end of a hydraulic cylinder goes into a tube that squeezes water into the gas cylinder. The gas cylinder is tested according to a motion profile dictated by a program running on the motion controller. Very high pressures can be achieved quickly, even though the cylinder’s piston is moving relatively slowly. Because the piston moves slowly, the pressurization system achieves long life.

Kishel has seen that using the Delta Computer Systems motion controller allows the system to achieve its target pressure to within 1% at 3000 psi. The motion controller gives Catalina’s testing process more precise control and a higher degree of repeatability in the pressure being applied than when using other techniques.

Conclusion:

Electronic motion controllers can excel at controlling force and position to generate real-world testing scenarios with exceptional results. Designers should look for motion controllers that provide precise closed-loop control and are supported with easy to use software and communication interfaces that simplify data collection, programming, and tuning of testing profiles.For more information, contact the author at [email protected] or visit www.deltamotion.com.