Erskine Attachments builds attachments for skid-steer loaders, compact tractors, and excavators. The firm’s heavy-duty forestry-mulcher attachment cuts, clears, and grinds brush, trees, and other vegetation. The attachment can be used for breaking trails, leveling building sites, and removing storm damage. The mulcher housing contains a 14-in. diameter, 60-in. wide rotary drum fitted with 30 double-helix, carbide-tipped steel teeth designed to pull material toward the attachment, where it is shredded.

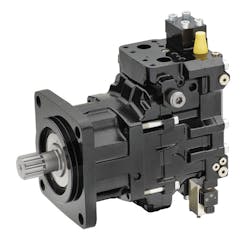

An early design decision was made to drive the mulcher’s drum with a variable-displacement hydraulic motor to give top performance automatically at both high and low cutting speeds. Erskine wanted a combination of speed and torque that could tackle any situation the mulcher faced in the field. To do this, the machine has to cut lighter material at high speed to boost productivity, without sacrificing high torque at low speed for grinding big trees. The firm selected the Parker Hannifin V14-110 bent-axis motor to meet these challenges.

Connected in an open-loop circuit, this nine-piston motor is housed inside the forestry mulcher structure. A belt sheave, mounted directly on the motor shaft, powers a cogged belt to drive the cutting head. The nine pistons provide high start-up torque and smooth operation. This large-frame motor envelope is robust enough that it doesn’t need an overhung load adapter, simplifying the design considerably. This arrangement worked well through all of Erskine’s early testing — even when the mulcher was heavily abused (abuse testing being part of Erskine’s procedures.)

However, one problem arose. The drum that this motor spins in the mulcher weighs 750 lb. When the skid-steer’s directional valve was centered to stop the motor abruptly, the drum’s inertia produced cavitation. This is bad for any hydraulic motor, but especially so for piston motors, where imploding bubbles can cause severe damage. Different plumbing configurations were tried over several weeks to resolve the problem, but none eliminated the cavitation.

Finally, a forestry-mulcher attachment was sent to Parker Hannifin’s Mobile Systems Team in Elk Grove Village, Ill. This team assists Parker distributors and OEM customers with design and performance problems. Its solution to the cavitation problem was to install an accumulator and then add a special check-valve manifold (mounted on the motor).

The accumulator stores hydraulic energy to ensure the motor inlet is always supplied with pressurized fluid. The check valve directs pressurized fluid to the motor and keeps it from flowing back into the motor supply line. Thus, the system is full of oil under any condition — even while the motor winds down to zero speed when the mulcher is turned off or when the loader’s engine speed drops under a heavy load.

Parker rented a skid steer loader to make sure it duplicated exactly what Erskine’s customers would see out in the field when the mulcher is doing real work. The modified design was a success — the cavitation problem disappeared.

The V14-110 motor has other features that make it attractive to Erskine. The motor shift pressure can easily be adjusted at the Parker Hannifin facility, at Erskine’s plant, or in the field — with just a wrench and screwdriver. The adjustment screw is located under a tamper-resistant plastic cap. (However, users should not change the settings without proper training.)

This adjustment feature allows Erskine to purchase one motor with a preset displacement range and then have it tuned for two different shift pressures dictated by the maximum operating pressure of the loader on which it will work. This adjustability helps the firm maintain a smaller inventory and shorter lead times.

The V14-110’s displacement range (minimum to maximum) can be adjusted, a feature not utilized by this application. Instead, two different-sized sheaves are used to change the speed ratio between the motor and cutting head.

One final plus: Due to the motor’s efficiency, no secondary cooler is needed on the cutting head. Coolers add considerable cost and decrease the overall hydraulic system efficiency.

Shane Voxland, Engineering Manager at Erskine Attachments Inc., Erskine, Minn., described this design evolution. Learn more about the company and its products at www.erskineattachments.com