There is much going on in the world of fluid power and motion control from technology introductions and industry advancements to new trends and industry leaders. To keep our readers as informed as possible, the Power & Motion team has collected some of the latest industry news.

Keep an eye out for a new edition each week to ensure you stay up to date on what's happening in the world of fluid power and motion control.

Timken Executive Elected STLE President

The Society of Tribologists and Lubrication Engineers (STLE) has elected its president for the 2022-2023 term, Ryan Evans, Ph.D., director of research and development for The Timken Company. Evans assumed his one-year term May 17.

As president of STLE, Evans will be the principle executive officer of the organization and act as chairman of its board of directors, says STLE in its press release announcing his appointment. He will also be tasked with creating a strategic plan to highlight the technology advancements, educational efforts and global advocacy taking place in the tribology and lubrication industry.Evans became a member of STLE's Board of Directors in 2015 and its Executive Committee in 2019; he held various leadership roles as part of those memberships.

"STLE is leading the charge for recovery, and my goal as president is to help the tribology and lubrication sector emerge stronger from the pandemic," said Evans in the STLE press release. "By bringing this highly technical and diverse community back together and leveraging our extensive resources for technical research, education and professional development, we can create a new path forward for innovation."

SKF Partners with Amazon Web Services for Predictive Maintenance of Industrial Machinery

SKF has formed a partnership with Amazon Web Services Inc. (AWS) to jointly develop a solution which will aid predictive maintenance and industrial machine reliability. The companies plan to create an easy-to-use and easy-to-scale condition monitoring and analysis solution says SKF in its press release announcing the partnership. SKF says this new solution will make it easier for a broader range of applications and customers to collect and analyze data using machine learning technologies.

SKF's knowledge of rotary machinery and predictive maintenance will be combined with AWS' Industrial AI services which pair AI and machine learning technologies. Sensors, gateways and a machine learning service will be among the components utilized; the companies intend to make these easy to install, commission and scale.

The companies also plan to collaborate on the next generation of SKF's data analysis platform the company says in its press release.

With this new solution, machine alerts and alarms can be sent to manufacturing personnel to help them better plan and manage maintenance. It will be available for any size manufacturer.

Volvo Trucks Opens New Battery Facility

Volvo Trucks has announced it will open its first battery assembly plant. Ready-to-install batteries will be produced at the facility, located in Ghent, Belgium for use in Volvo fully electric heavy-duty trucks.

The company will assemble battery cells and modules from Samsung SDI into packs which are tailored to the specific design needs of Volvo Trucks' electric vehicles. Volvo Trucks expects series production for the battery packs to begin in the third quarter of 2022.

"By integrating the battery assembly process in our production flow, we can shorten lead times for our customers and secure high-performing batteries, while at the same time increase circularity," says Roger Alm, president of Volvo Trucks, in the company's press release announcing the new facility.

In addition to powering Volvo's electric trucks, the batteries are designed to be remanufactured, refurbished and reused, which will help further extend their lifespan.

The company says the new facility is also powered by 100% renewable energy.

Danfoss Appoints New President of Hydrostatics Division

Danfoss Power Solutions has appointed Tony Welter as president of the company's Hydrostatics division. Welter is based in Eden Prairie, Minn., and came to the company from Eaton Hydraulics which was acquired by Danfoss. At Eaton he held the role of vice president of the Fluid Conveyance division.

In his new role Welter will report directly to Eric Alström, president of Danfoss Power Solutions. Welter is replacing Astrid Mozes, who has moved on to the role of president of Danfoss Developing Regions."I’m very excited about working with our talented Hydrostatics division team, who share the same passion for providing innovative, value-added solutions to our customers," says Welter in Danfoss' press release announcing his appointment. "I take great pride when I see equipment in the field or on a construction site that is powered by a Danfoss hydrostatic solution. Our products are making a difference across the industry, and that is very rewarding. In addition, we have a strong development pipeline of new, innovative technology and solutions that will fuel growth and provide our customers with increased levels of efficiency and productivity."

Mack Trucks Makes PreView Collision Warning Technology Available

Mack Trucks announced during the recent WasteExpo 2022 event that Sensata Technologies' PreView multi-sensor collision warning system will now be available on the Mack LR, Mack LR Electric and Mack TerraPro truck models. These types of vision systems are becoming increasingly important not only to improve safety but also as a component of autonomous systems and vehicles.

The system uses four radar sensors positioned around the vehicle to detect objects and Vulnerable Road Users (VRU) such as pedestrians and cyclists which could be in a truck driver's blind spot. If an object or person is detected, audible and visual alerts are given to the driver. Mack Trucks says the system is available as an option and is factory-installed on new build trucks.

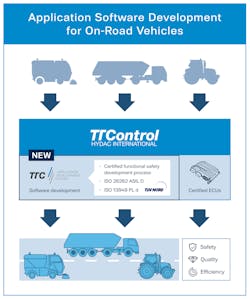

TTControl Receives ISO 26262 Certification

TTControl, part of HYDAC Group and TTTech Group, has received ISO 26262 certification for its software development processes from TÜV Nord. This ISO certification is a requirement for many vehicle control unit functions, and receiving it ensures customers using TTControl's products will be compliant without having to invest a lot of time and effort in certification processes.

"As our electronic control units have been certified, our application development processes follow. We offer a certified quality standard for individual applications and support the customer throughout the vehicle certification process for successful software certification according to ISO 26262," says Janosch Fauster, director of TTControl's Application Development Center, in the company's press release announcing the certification.

TTControl notes in its press release the set up of an ISO 26262-compliant process can cost vehicle manufacturers over 5,000 hours in time and financial investment. There is also work that must be done to continue fine tuning it over the years. With TTControl's certified process, OEMs can accelerate this process while ensuring compliance.

TÜV Nord has certified 35 of TTControl's processes for vehicles over 3.5 tons. It was recently used to help optimize safety certification's for the Rosenbauer RT—a hybrid-electric firefighting vehicle developed by OEM Rosenbauer with whom TTControl has partnered. This helped to ensure the functional safety of the vehicle's hybrid-electric architecture.