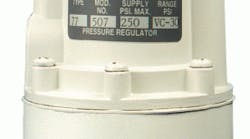

They feature aluminum die-cast construction with weather-resistant vinyl paint finish. Output pressure droop under varying downstream flow conditions is minimized by aspirator tube, which adjusts the air supply valve opening in accordance with flow velocity. The dampening action of the aspirator tube maintains continuous and stable output pressure.

It provides precise vacuum pressure control within sub-atmospheric monitoring applications. It can be installed upstream or downstream from the vacuum pump. Upstream installation is preferred for applications in which the rapid evacuation of a vessel or system is required, because pump exhaust capacity is normally greater than that of the regulator. In all other applications, the regulator can be located between the pump and the vessel. Units may be either pipe-, panel- or bracket-mounted to suit particular application needs.

The Precision Controls Division of Marsh Bellofram Corp., (304) 387-1200, www.marshbellofram.com