The addition of electronic control to pneumatic pressure regulators enables accurate and repeatable pressure control. According to Jon Lister, Manager of Technical Development at Proportion-Air, these electro-pneumatic devices provide more precise control and make it easier to integrate them into automation applications.

“Process automation becomes easier with the electro-pneumatic part compared to a manual regulator [where] you have to get somebody to turn a knob or get really fancy with needle valves and pneumatic logic,” he said.

With electro-pneumatic control, the pressure regulator automatically adjusts the flow of compressed air as needed which benefits the technology’s use in a range of applications.

Electronic Control Achieves Better Pressure Regulation

Electro-pneumatic pressure regulators are closed-loop devices which control compressed air or gas pressure for pneumatic systems. An electronic input signal is sent to the regulator by a programmable logic controller (PLC) or other device which causes it to adjust pressure for the system.

These pressure regulators are comprised of two control valves – an inlet and an outlet valve – a pressure sensor, and electronic controls. When a command is sent to the regulator, the amount of pressure in the system detected by the sensor determines actions taken by the control valves.

If a command is sent to increase the amount of pressure in the pneumatic system, for instance, and the sensor determines the pressure is low, an electrical signal is sent to open the inlet control valve to let in more air.

Inclusion of a pressure sensor and electronic controls overcomes the need to manually adjust a regulator while ensuring more accurate tuning to application requirements. It also helps overcome issues associated with earlier electronic versions in which a flapper is used to adjust air flow. “If the pressure going into the regulator changes, and you're just controlling how open or closed the valve is, then the outlet pressure is going to change,” said Lister regarding the challenges associated with these earlier designs.

He noted the internal components of early electronic devices were not as robust either. The valve inside the regulator could move around, causing output pressure to change and thus potential performance issues for the pneumatic system. “You couldn’t put it on the end of a robot because every time you swung the robot, your pressure would be changing,” he explained.

Lister said electrical and hydraulic options are the biggest competition to electro-pneumatic control. While there are some applications in which those technologies do fit better, there are a wide variety of others for which electro-pneumatic is the right solution.

He said in the past, electrical control was typically better for providing the precision required of positioning applications. But with Proportion-Air’s two-loop QB2X pressure regulator, it is possible to get as good as, if not better, control over electrical.

With the QB2X, you can integrate a position sensor with an air cylinder and plug the sensor directly into the QB2X to allow for position control without having to utilize another PLC.

“Using the second loop technology, you can control speed, torque, or whatever you’d like,” said Lister. “If there's a sensor out there for it, we can hook it up to the QB2X.”

Hydraulic control is typically for those applications with high force requirements, typically in the tens of thousands of psi. However, Lister said Proportion-Air does have electro-pneumatic components, including the QBX pressure regulator, which are capable of achieving higher pressures. The company’s GX unit directly drives up to 1,000 psi.

For higher pressures, ratio regulators are available for the QBX which increase the amount of pressure that can be controlled. “We’ve controlled up to 7,500 psi,” he said. “We know from the process and part availabilities we can go up a little over 20,000 psi but no one has really had the application for that yet.”

Applications with space or size constraints may also factor into the ability to use electro-pneumatic control. “If you don’t have compressed air or ways to fit hoses in, then you can use electrical for [applications] that need some precision,” said Lister. “Sometimes it is not worth putting a whole compressor in if there is just one little part that you need the precision on.”

READ MORE: Advanced Electropneumatic Positioning Achieves Dynamic Force Control

Applications Benefitting from Electro-Pneumatic Pressure Regulators

Determining the applications for which electro-pneumatic pressure regulators like Proportion-Air’s QBX are best suited is difficult because they control process variables. “That’s such a wide variety of things,” said Lister. “It’s like asking what’s the best benefit for a screw? It really depends on what you’re using it for; the benefits really vary wildly.”

He said the pressure regulators are commonly used in automation related applications, and have proved particularly beneficial for manufacturing semiconductors, medical devices, and automotive components.

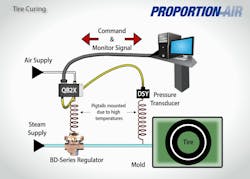

One example he provided was controlling steam temperature for tire curing. Ensuring the correct temperature is reached and maintained throughout the curing process is critical to creating a safe and high-quality tire.

Traditionally, an air-piloted steam control valve is used to throttle or modulate the flow of steam to achieve the correct temperature for tire curing. However, because these valves are made to control flow it is necessary to program a PID loop which introduces latency into the process and thus it takes a long time for the desired steam temperature to be reached and maintained.

Proportion-Air’s electro-pneumatic pressure regulators can take advantage of the direct relationship between pressure and temperature for saturated steam – because the steam is supplied at a specific pressure, controlling pressure is controlling temperature. There is no longer a need for a PID loop to find the correct set point; the pressure regulator can do so, in a quick and efficient manner, enabling steam to reach the appropriate temperature in about 10 minutes compared to the typical 45 minutes with air-piloted control valves.

The company’s pressure regulators aid with other parts of the tire manufacturing process as well where intense heats or specific pressures are required such as tire balancing, uniformity testing and tire inflation.

READ MORE: A Primer on Pneumatic Pressure Regulators

The improved performance and extended capabilities provided by electro-pneumatic control in these, and other applications are helping drive further interest in the technology as well as the use cases for it. “It’s interesting to see how just being able to control a small amount of air can affect so many things,” said Lister.

Electrification and automation of systems are among the industry trends helping drive increased use of electro-pneumatic technologies due to the precision and efficiency provided as well as the fact there are more electronics being incorporated with mechanical components.

In recent years the development of machines capable of doing multiple things have become available for the manufacturing sector which Lister said is a good use case for electro-pneumatics. “Now you can have one regulator that's controlling [a robot] gripper arm and you can change the pressure of that gripper arm [based on] whether you're picking up a little plastic die or a big metal ball,” he said. “You can use the same gripper and the same Proportion-Air regulators like the QBX.

“As we’ve seen manufacturing grow pushed by the reshoring effort, we’ve been really involved in what we call retooling America, trying to get [the country] back up to speed like we once were, and like countries all over the globe are doing right now,” he said.

Continued improvements in sensor and valve technology in the coming years will lead to further improvements in the capabilities of electro-pneumatics as well. “And we’re going to be right there on the cutting edge of that. [We have] R&D labs where we’re just constantly testing out new parts and trying to reach new levels of control and performance for everybody,” he concluded.

Watch our video interview with Jon Lister, Manager of Technical Development at Proportion-Air, for more details on the Proportion-Air QBX electro-pneumatic pressure regulator.