Weighing in at about 25,000 tons, the jack-up rig slowly rises out of the sea and comes to a stop high above the waves. These installation platforms serve the booming offshore wind farm market and are indispensable because their legs stand firmly on the seabed, even in rough seas. Work can be carried out safely, quickly and with a significantly wider operating window against hostile conditions.

High reliability

Bosch Rexroth has supplied jacking systems to offshore industries since the early 1960s. This experience has led to the development of hydraulic jacking systems capable of generating axial forces exceeding 25,000 tons. Following evolutionary development of the original concepts to create semi-automatic, double-yoke systems, Bosch Rexroth introduced the continuous jacking system more than two years ago.

Great demands are placed on these powerful jacking systems. Equipment owners expect service life of 25 years or more, in spite of wind, weather, seawater, and enormous loads. To maintain high reliability and operational safety, engineers had to eliminate the risk of fatigue failure. To do so, they developed specific designs for the cylinders and piping. Piston rods in the jacking cylinders are coated with Ceramax, a ceramic finish well-suited to the harsh conditions of the open sea. This coating is also an integral part of Bosch Rexroth’s Ceramax Integrated Measuring System (CIMS). The CIMS is a magnetic measuring system that transmits high-resolution linear position feedback to the jack’s closed-loop control system. It ensures precise, accurate movement and leveling of the offshore platform during operation.

A question of precision

Software developed for the jacking system provides smooth transitions between various operating modes, pressures, and loads — thus helping to reduce wear. It guarantees exact control of all acceleration and deceleration phases, parallel and opposing cylinder strokes, and smooth transfer of heavy loads. In addition, it enables automatic transition between the four operating modes, i.e. leg lowering, platform lifting, platform lowering and leg lifting.

A notable challenge is the transition between positioning the legs onto the sea floor and lifting the platform because the platform follows the rise and fall of the ocean. As a result, enormous forces act on the entire jacking system.

This transitional phase requires tight position and speed control. The continuous jacking system hoists the platform out of this critical situation faster than a lifting system that operates intermittently.

Savings achieved

The control software and drive assemblies not only provide for high speed during lowering and lifting, but also economize on power consumption. Bosch Rexroth’s HS4P control provides closed-loop pump displacement control using a directly controlled proportional valve and displacement feedback transducer in each pump. The pumps also have integral transducers for closed-loop pressure control.

The HS4P controls not minimize energy consumption of the jack’s two hydraulic pumps, but also regulate pressure for a crane or winch.

The owner benefits from integration of multiple hydraulic functions, which allows incorporating redundancy while holding manufacturing costs down. This lowers investment costs for the ship by combining high performance with low power consumption, reduced space needs, and lighter weight, which reduces power requirements of cranes.

Overall, this new hydraulic continuous jacking system supports the tremendous rise in demand for installation platforms.

For more information about Bosch Rexroth’s drives and controls for wind turbines , visit www.boschrexroth.com.

How the jacking system works

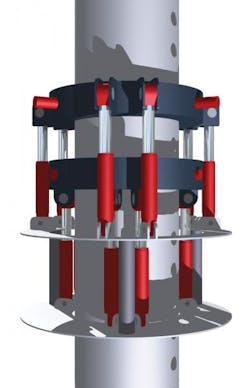

The principle is simple: The jacking system climbs up or down the platform’s legs, much like a caterpillar. Two yokes surrounding each leg are fitted with sets of holding pins. The first yoke snaps its pins into holes along the leg. Cylinders of this first yoke then lift the platform.

By the time the first yoke’s cylinders have nearly reached the end of their strokes, the second yoke has moved into position to insert its set of pins in the mating holes. Once inserted, these pins at the second yoke bear the load. The pins at the first yoke retract and the cylinders raise the first yoke so that its pins can again assume the load in the next position.

This continuous jacking system prevents interruptions during lifting and lowering operations. It also attains a constant jacking speed of one m/min or higher while using synchronized position feedback to keep platforms level at all times.