Technicians were performing preventive and predictive maintenance inspections of a press and noticed a noise change in the hydraulic unit’s piston-pump. It sounded like a knocking noise that had a 30-Hz (30 knocks per second) signature. The workers checked the pump’s case-drain flow when the pump compensated, but it had not changed since the last inspection. Oil sampling and analysis revealed that the fluid’s ISO 4406 code was better than the system required.

We asked them what, if any, service was performed recently. They had changed the return filter element when they had to replace the pump’s suction hose that someone stepped on and kinked. The work team felt the damage warranted changing the hose.

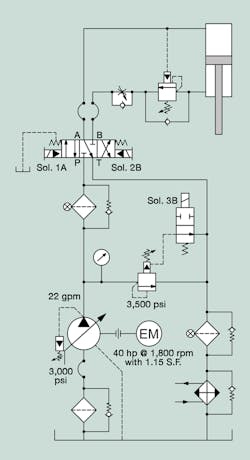

A schematic of the hydraulic system is shown. If it looks familiar, it’s because a previous Troubleshooting Challenge dealt with a problem on this same machine, where a solenoid sticking on an electrically unloading relief valve prevented the electric motor from being able to start the power unit’s hydraulic pump.

Any idea what was causing the knocking noise in the pump?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct answers submitted by Aug. 18, 2019 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Terry Turner, maintenance manager at Claude Howard Lumber Co., Statesboro, Ga., whose name was chosen from those who correctly answered last month’s challenge. A $50 gift card is in the mail to him.

Solution to Last Month’s Challenge:

O-rings Missing from Valve Stack

Size D-03 valve modules from Sun Hydraulics can be installed in any of four different positions by turning the module 180 deg. or 90 deg. to the left or right from an initial position. Sun uses a thin, separate O-ring plate to accommodate the different positions. We found the module was rotated at one time to the position that had the anti-cavity check free-flowing from the tank port to the B work port. With the P (or T) port facing me, I rotated the module 180 deg. from my left to my right, eliminating the problem.