A construction supply house that caters to construction contractors has a tractor-trailer rig with an articulated arm for material handling. It operates as a forklift boom by picking up skid loads from the trailer bed and placing them at the construction site to expedite loading and unloading time.

A problem developed when operators had to readjust the arm’s counterbalance valve every time the load weight changed. They could lift varying sizes of loads and set them on the trailer. However, when they went to lower the load to set it either on the trailer bed or on the ground, it would fall unrestricted. This posed a serious safety problem, requiring them to adjust the counterbalance valve so it would not drop in an uncontrolled motion.

Another problem they found was when the boom was lowered without a load, pump pressure ramped up to the compensator setting and the arm run very slow when lowering.

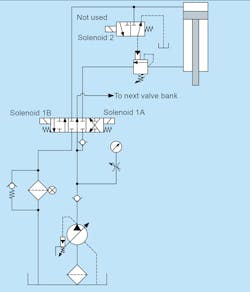

The circuit for the valve bank section with the problem cylinder is shown. Any idea what’s causing the problem?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct answers submitted by August 17 8, 2018 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Challenge:

Ink-Mixing Drum Slows After Startup Solution

All hydraulic systems have designed and consequential clearances that result in internal leakage that increases as a function of the pressure differential. Some of the designed leakage is necessary for lubrication while other leakage is undesirable.

As hydraulic oil temperature increases, its viscosity thins out. Thinner (more like water consistency) will leak quicker with the same pressure differential. Without some external feedback to adjust the command signal, all hydraulic systems will slow down as the oil heats up. Using an oil with a higher Viscosity Index number would reduce the leakage. The manufacturer’s recommendation required an Index of 100 or more while the oil they were using was less expensive and far below the VI-100. Using the correct VI oil reduced the leakage to an acceptable 5 to 10% change.