This file type includes high-resolution graphics and schematics when applicable.

In the world of fluid power, one of the least-complex components is the shuttle valve. Operating on that premise, you may think you know all there is to know about them. Shuttle valves perform the simple function of allowing flow from an outlet port from either of two inlet ports while blocking flow to the other. A shuttle valve may look like two check valves mounted back-to-back, but that isn’t the case. While opposed check valves allow flow from one of two ports to a third, they block flow from the outlet to both inlets.

Non-biased shuttle valves have two inlet ports and a single outlet port with flow direction controlled by fluid pressure. The inlet port with the higher pressure passes flow to the outlet port, while flow is blocked from the other inlet port. A biased shuttle valve incorporates a spring that acts against inlet pressure at one of the ports. Fluid from that port cannot flow unless its pressure exceeds pressure at the opposing inlet port plus the pressure to overcome the spring force.

Shuttle valves also allow reverse flow—fluid from the outlet port flows back through either of the inlet ports. This important characteristic distinguishes shuttle valves from check valves placed back-to-back. In dead-ended circuits, such as pilot and brake circuits, system pressure must be able to relieve when the input pressure drops, which occurs with the shuttle valve.

Shuttle-Valve Function

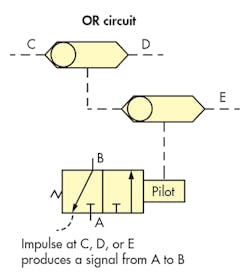

The shuttle valve is essentially an OR logic element (see above). One input or the other becomes the output, usually a pilot signal that controls a normally open or normally closed valve. The circuit shown is an OR circuit, with the OR elements (shuttle valves) connected to a normally closed valve. Substituting a normally open valve, the circuit becomes a NOR circuit, where any input stops the output.

Shuttle valves are naturals for switching alternate, standby, emergency, pressure, or power systems, and are essential for dual-input pilot control. A free-ball shuttle valve with leak-tight sealing on the closed port, short ball travel, and low-pressure shifting (such as Kepner’s 2450 series) provides reliable performance at pressures to 3,000 psi (see also "Flexible Seal Seat Ensures Bubble-Tight Performance").

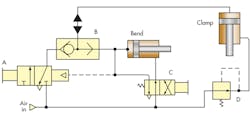

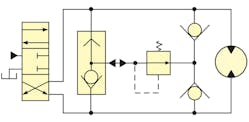

Clamping and bending—Valve A above applies air to the up end of the clamp cylinder through shuttle valve B. The operator then actuates valve C to extend the bend cylinder and reset valve A. Shuttle valve B maintains pressure in the clamp cylinder. When the operator releases valve C, low-pressure air from reducing valve D retracts the clamp cylinder. The pilot line of valve A is vented, and the system is ready for the next operation.

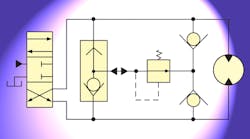

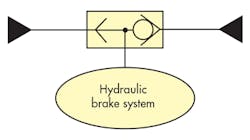

Winch brake—The shuttle valve provides brake control in this hydraulic winch application shown above. When the hydraulic motor is energized in either direction, the shuttle valve directs fluid to open the brake shoes. When the control valve is centered, the brake cylinder vents through the shuttle valve, allowing the brake shoes to close.

Alternate power inputs—Above, the shuttle valve allows instant change of control from one station (or master cylinder) to the other. Many vehicles and systems are equipped with alternate control stations or two driving stations with separate hydraulic inputs. The shuttle valve directs these to the required output.

Fluid motor crossover—The shuttle valve in the brake and crossover circuit shown above separates the high- and low-pressure circuit branches and directs fluid to the relief valve. Here, the shuttle valve replaces back-to back check valves.

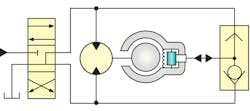

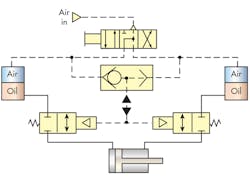

Air pilot control—Converting from air to oil can lock a cylinder in place. Shifting the 4-way valve to either extreme position applies pilot air through the shuttle valve to hold the two air-operated valves open and apply oil under air pressure to the corresponding end of the cylinder (see above). Positioning the directional valve to neutral lets pilot pressure exhaust. The 2-way valve then closes and traps oil on both sides of the cylinder to lock it in position.

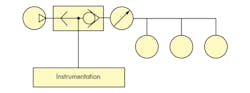

Standby and emergency systems—Pressure control of multiple compressors requiring standby or purge gas capability can be accomplished simply by using a shuttle valve. Examples include instrumentation, pressurized cables, or any system requiring continuous pneumatic input. If the compressor fails, the standby bank (regulated to slightly lower than compressor supply) will shift the shuttle valve and take over the function. The shuttle valve will close the compressor inlet port to prevent losing system pressure. When compressor pressure is reestablished, the shuttle valve shifts back and seals off the standby system until needed again.

David Broschka is assistant general manager at Kepner Products Co., Villa Park, Ill. For more information on shuttle valves and Kepner’s other line-mounted and cartridge valves incorporating Flexible Seal Seat technology, call (630) 279-1550, e-mail [email protected], or visit www.kepner.com.