This article was originally published in the January 1993 issue of Hydraulics & Pneumatics.

While walking through the International Fluid Power Exposition in Chicago last spring, I couldn’t help but notice the large number of exhibitors who displayed the term motion control. What is going on here? Is there something in this new buzzword that requires some further investigation? The answer, in my opinion, is an unqualified and resounding yes!

Motion control is a unique technology, as evidenced by the interest among industry’s engineers. But the technology remains in its formative stages. I believe it essential for practitioners of the fluid power art to be involved in this early stage of development, lest we be excluded from those industries that can benefit from the excellent motion-control attributes that fluid power offers.

E.A. Ross, a consultant with Ross Associates, defined motion control in a technical article as, “The precise control of position using an input control signal and an actuator consisting of a servoloop, or an incremental driver of similar precision.” Personally, I disagree with this definition because it contains the subjective term “precision,” and reasonable and knowledgeable engineers will disagree on the meaning of precision. Furthermore, the definition lists the constituent parts of the system. The last phrase is there, I presume, to accommodate the stepper motor industry.

A Universal Definition

Too many readers, I fear, will interpret the above definition to mean that only electrical actuation is suited for industrial motion control. Such is simply not the case. Therefore, we need a definition with which all engineers and technical specialists can identify, one that does not exclude any type of actuation medium.

If we define motion control in terms of what it contains, the list of possible constituent parts becomes endless—and so does the definition. But, more importantly, Mr. Ross’s article goes on to list the “industry leaders” in the constituent parts, including fluid power component manufacturers. I suspect Mr. Ross’s background is in military or aerospace because his list, it seems to me, is slanted in that direction. If true, this is unfortunate because the future of America lies not in its military and aerospace hardware, but in the commercial, industrial, and manufacturing sectors.

I prefer to define motion control in terms of its objective, and in my book, Design of Electrohydraulic Systems for Industrial Motion Control, I offer this definition:

“Simultaneous control of acceleration, velocity, and position.”

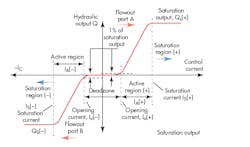

Indeed, this is what fluid power engineers are in the business of providing. The degree of precision is a function of the application and the job that must be done. Sometimes, a proportional valve will suffice. In other cases, only a servovalve will work. In fact, at specification time, it is difficult to determine whether a given set of system requirements is “precise” or “imprecise.” Only an engineering evaluation will reveal that.

For example, obtaining a positioning error in steady state of, say 0.020 in. with a total travel of 60 in. can represent a formidable design challenge, whereas, 0.001 in. of error with only 4 in. of stroke sometimes is easily accomplished. On the other hand, if the load becomes 50,000 lb and cycle time must be less than one second, the likelihood of success is reduced. These are simple examples of the motion control specification process. Ultimately, however, a large number of usually conflicting requirements and hardware parameters must be brought together to design a workable system.

The components and adjustments (tuning) needed for a successful application are not always obvious at the outset. Most systems require extensive calculation and evaluation. Thus, the application engineer must proceed from specifications to system design by assuming that a solution to the problem at hand lies in motion control. Subsequent component evaluation then will yield the degree of precision needed and reveal whether closed-loop servo control is needed. Only those engineers trained in designing the highest level of system sophistication are in a position to decide if a lesser level of sophistication is acceptable.

Learn More About Motion Control

The application of motion control technology to electrohydraulics and electropneumatics involves a design philosophy wherein the designer strives to gain total guided control of an entire machine through its entire production cycle. This philosophy is a scientific approach so it leaves less of the outcome to chance than with the currently popular intuitive design approaches taught in too many of our colleges and universities.

The objective of this discussion on motion control technology is to raise three important points:

- Think of motion control as cutting-edge and exciting technology. The future of fluid power is tied to the future of motion control technology and its application; we can contribute to and learn from its advancement.

- Motion control is a technology that includes not only fluid power actuation and power transmission, but also electronics, physics, kinematics, and a host of other technical specialties. It can be a vehicle that academia uses to create curricula that are truly system oriented, rather than the traditional course separations of mechanical, chemical, electrical, etc.

- This new department in Hydraulics & Pneumatics will introduce some of the motion control design technology without resorting to advanced mathematical concepts, such as Laplace transform calculus and modern control theory. This point is not meant as an indictment of such analytical tools, but, rather, as a statement that it is possible to design useful, functioning motion-control systems without resorting to such advanced mathematical analyses, however powerful they may be.

Fluid Power and Motion Control

Motion control is a technology separate from, but related to, fluid power, and we can learn from the advances already made in electrically actuated machine tools and robots. Applying motion-control technology allows us to simultaneously increase machine productivity, reliability, product uniformity, and customer satisfaction and loyalty while reducing shock and manufacturing costs!

Design of electrohydraulic and electropneumatic motion-control systems has some fascinating—but challenging—aspects. For example, understanding hydromechanical resonant frequency of a system helps explain how it limits a machine’s maximum possible cycle rate. Future articles [which have already been published] deal with the physics of motion control, including synthesis of a motion control profile, proper sizing of a control valve to achieve the required degree of control, and discussion of frequency response and system bandwidth (another name for system frequency response).

Double Deal on Textbook

Now you can get the original book that started electrohydraulic motion control education and training. No other book gives you the methodology for the optimal design of electrohydraulic motion control. It’s all laid out for you. You will find all the background and root sources for correctly sizing components, designing control systems, closing the control loop and much more. Anyone interested in, or with a need to design electrohydraulic motion control systems will find this book an absolute must and an essential addition to their technical library.

The third edition of Design of Electrohydraulic Systems for Industrial Motion Control, by Jack L. Johnson, P.E., contains 380 pages and sells for $109. Order before March 16, 2018, and receive a free copy of Fluid Power systems and Circuits, by Russell W. Henke, P.E., and free shipping within the U.S.

For more information about the book or to ask a question about its content, e-mail the author.