The use of variable-speed electric drives to power hydraulic pumps has grown with the development of high-speed controls, quick-response motors, and improved software that give these motor-pump combinations the power and responsiveness to match systems controlled by electrohydraulic valves or a variable-displacement pump, while also reducing energy consumption.

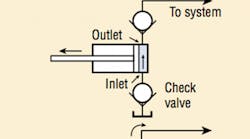

Traditionally, constant-speed ac induction motors have been used to drive the pumps in stationary hydraulic systems, with hydraulic power controlled by flow- and pressure-regulating valves or a variable-displacement pump. However, the constantly-running motor can consume as much as 50% of full-load current, even when the system is not under load. In addition, pumps and motors in conventional hydraulic power units (HPUs) often are oversized to meet maximum duty-cycle demands. By contrast, a variable-frequency drive or servodrive can manage an electric motor’s operating torque and speed more efficiently. Instead of running continuously at full speed, the motor rotates only fast enough to meet system demand at any given time.