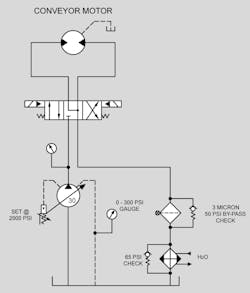

A simple 2,000-psi hydraulic system was designed and installed to run a conveyor in a hog-processing plant (see schematic). Two belt conveyors at a vertical angle to each other create a V shape, with about a 12-in. gap at the bottom and about a 30-in. gap at the top. A flat floor at the bottom of the conveyor slopes down from the entrance. Hogs travel down single file into the conveyor. As they enter the conveyor, the sloping floor causes the hogs to be wedged in and carried to where they are dispatched, and processing begins.

The new system developed a problem with the C-face mounted pump shaft seal failing after six weeks or so. The seal lip with a garter spring was pushed out. The maintenance crew replaced the seal and was told by the power-unit builder that this type of failure was normally due to excessive pump case pressure. The crew installed a standard 0- to 300-psi pressure gauge teed into the case line to monitor case pressure.

They observed it for several hours, then every day for a week or two. They noticed that when the pump compensated each time the conveyor was stopped, the pressure would spike between 10 and 15 psi but then only read about 5 to 8 psi. When the directional valve was shifted to run the system, the pressure would drop even lower.

The pump shaft seal failed again five weeks later. The power-unit builder said case pressures this low shouldn’t cause these failures, but they did not know what could be causing the failures.

Do you have any ideas?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct answers submitted by May 22, 2018 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Tony Casassa, of Andover, Minn., whose name was chosen from those who correctly answered last month’s challenge. A $50 gift card is in the mail to him.

Solution to Last Month’s Challenge:

Deburring Tumbler Doesn’t Stop Turning

Once it was coasting, the de-burring drum relied on the hydraulic motor’s brake valve to stop the rotation in a given time. There were anti-cavity check valves built into the screw-in valve cartridges. One of the check valves had picked up a piece of aluminum and remained open allowing the drum to drift. The mechanic who resolved the problem had switched the cartridges and found the problem occurred in the opposite direction.