A foundry that produces aluminum castings uses a large drum-type tumbler to deburr raw castings. The foundry uses clamshell-type molds, and once they are closed, molten aluminum is poured into holes (sprues) to fill the mold cavities. Upon completion, the molds are open, leaving a thin line (flash) around each part where the mold halves came together. A raised spot (sprue) is also left where the aluminum was poured in.

The castings are dumped into a large deburring tumbler, which is half filled with small, smooth stones and a water spray. The tumbler is driven by a hydraulic motor that transmits the high torque and low rotational speed needed for this application. After rotating several revolutions in one direction, the motor then stops and rotates in the opposite direction. This cycle repeats several times until the castings have the desired surface finish. Once this occurs, a timer stops the drum and signals that the parts are finished. An operator then opens a large door to access the parts. They use a pitchfork-type shovel with a long handle resting on the door edge for leverage and scoop up the parts, allowing the small stones to fall through the gaps.

An issue developed where the tumbler would stop in one direction but coast in the other. This caused a shock problem when it suddenly reversed one direction while the drum was still rotating in the opposite direction. Then when operators opened the door to unload the drum, it would start turning when they tried to scoop the parts out.

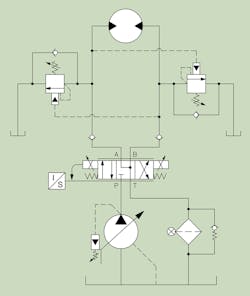

Referring to the accompanying schematic, can you figure out what caused the problem?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct answers submitted by April 22, 2019 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Gregory Palet, Fluid Power Specialist, of Minocqua Wis., whose name was chosen from those who correctly answered last month’s challenge. A $50 gift card is in the mail to him.

Solution to Last Month’s Challenge:

Electric Motor can No Longer Start HPU

When an electric motor is sized close to the horsepower nameplate rating, its minimum breakdown torque may be insufficient to meet the hydraulic pump’s required torque. Fixed-displacement and pressure-compensated pumps deliver full flow based on the speed of the motor at the system’s maximum controlled pressure. Silting in the spool actuated by solenoid 3B was stuck in the shifted position. This condition caused the motor to start under full hydraulic pressure, which required torque too high for the motor to produce.