Pulse-width modulation (PWM) has been used successfully in electronic control circuits for at least 50 years. It is an efficient method for controlling a large amount of output power while expending a relatively small amount of power in the controller itself. No matter how small, though, the sources of inefficiency in the electronic PWM circuit stem from the finite switching time of solid-state controlling devices and the finite conducting resistance of the switching device when in its on state. The extremely short switching times of electronic devices allow for the efficient use of PWM at frequencies in the kilohertz range, opening up a fairly wide array of suitable applications.

On the other hand, using PWM to perform hydraulic switching requires valves, whose switching times must be measured in tens or even hundreds of milliseconds—not microseconds or nanoseconds as in the case of electronic circuits. The result is that improperly implemented PWM hydraulic circuits produce unwanted vibrations and pulsations at frequencies that can be transmitted to output actuators. This possibility exists with the PWM-regulated hydraulic pressure source.

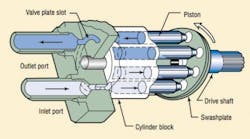

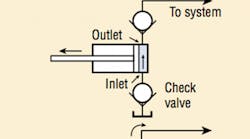

To investigate this phenomenon, I constructed a PWM-controlled, constant-pressure power supply typical of those used in electrohydraulic servomechanisms and motion-control systems. Representative test results can be displayed and analyzed, and others can use a practical design methodology to apply the PWM method to regulate pressure from a power unit supplying more than a trivial amount of power to a dynamic load. This applied engineering analysis aims to determine the extent a PWM-regulated pressure source can be constructed using a fixed-displacement pump with augmenting accumulator, as compared to the conventional method of using a pressure-compensated pump.

Effects of Non-Constant Pressure

Having constant pressure at the servovalve’s pressure port is critical in motion-control systems using the positional servomechanism that follows a motion profile. Motion-control system performance improves when constant pressure is maintained at the port. Non-constant supply pressures adversely affect the servosystem in three significant ways.

First, if the supply pressure varies when the servomechanism is in a dwell, or fixed position, the variations are propagated to the servoactuator in a way that upsets the force balance. Therefore, the actuator moves, seeking a new point of force balance. This results in a new value for the error signal, and, as its name implies, results in a positioning error. In a machine tool, for example, this can result in machined parts that must be scrapped.