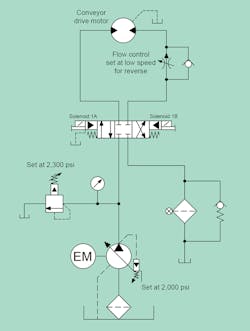

A simple conveyor transfers salvaged cast iron from an auto shredder to a large storage building. The shredding machine was recently overhauled, and one of the improvements resulted in being able to shred more cars per hour than before.

Operators sometimes had trouble getting the conveyor started when it was loaded. They discovered, though, that increasing the pump’s pressure setting solved the problem. However, hydraulic oil in the reservoir would overheat at times.

Plant personnel called a service technician to troubleshoot the overheating problem. He checked the case drain flows from the motor and pump and determined they were acceptable.

Any idea what the problem was?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct answers submitted by Feb. 18, 2019 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Challenge:

Two-Stage Directional Valve Locks Up

When installing replacement pilot-operated valves, it’s very important to verify the pilot pressure and pilot drain are configured the same as in the old valve that worked. In this instance, the replacement valve had a solid plug internally blocking the pilot drain Y connection.

Because the valve was not full of oil when it was received (and especially after disassembly and reassembly), the main spool would shift back and forth—compressing the trapped air in the pilot drain until the valve locked up.

Removing the solid plug blocking the internal drain of the pilot to the main tank port solved the problem.