Anyone who uses hydraulic equipment in the field knows that real-world conditions and test-bench conditions are worlds apart. The real world has dirt. The real world has stress. Variables. Real-world conditions are harder—if not impossible—to control, whereas testing situations are made to be controlled.

Hydraulic systems are tested in real-world conditions before being put on the market. The same should be said for the fluid filtration that protects hydraulic (and lubrication) systems. This is why the filtration testing standard should reflect those conditions as closely as possible. Current testing standards are simply not up to par.

Fortunately, the International Standards Organization (ISO) has taken note. With the likely approval to replace ISO 16889 with ISO/NWIP 23369 later this year, hydraulic fluid and lube multi-pass filtration will finally be held to a standard that applies cyclic flow conditions more similar to what hydraulic equipment sees in real-world applications.

Efficient Filtration is Vital to Any System

Efficient operation of hydraulic systems requires diligent maintenance, including thorough and efficient filtration. However, the current standard for hydraulic and lube tests, ISO 16889, does not factor in real-world filter performance. A hydraulic filter operating in the field typically is not subjected to the steady-state flow used in the current ISO 16889 testing. Instead, varying degrees of cyclic flow occur. It’s been proven that the efficiency and capacity of an element face greater challenges when subjected to more stringent testing and varying cyclic flow conditions—such as those that the ISO/NWIP 23369 would require.

This is why it’s important to review the performance of a filter under cyclic flow conditions. This new standard will affect everyone, from end users—who can now be more confident that their system is protected—to engineers designing hydraulic machines, who can now specify filters that will provide realistic results for R&D.

The purpose of the new standard is not to denigrate the current one; it’s a matter of times and technology changing. The industry is simply more capable of applicable testing for filtration products than it was 10 years ago. ISO/NWIP 23369 has been in motion since 2011or before, and technology finally caught up so that the industry can implement it.

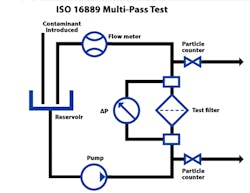

The current industry standard for hydraulic and lubrication filters, ISO 16889, details the design and construction of test stands, applications of contaminants, and procedures used during testing of filtration products. It’s a simple test that produces accurate and repeatable results. It uses a steady flow and medium test dust continuously injected into the filter’s reservoir. But of all possible tests for hydraulic filter effectiveness, it’s the furthest from real-world application and offers no accurate look at how fluctuation in flow rate can affect filter performance.

This schematic show the setup for the ISO 16889 multi-pass filtration test.

The main issue with the current standard is that we’re designing equipment for filters that can hold a certain amount of contaminant. In reality, though, filters cannot hold as much contaminant as they did in lab tests because the varying flow rates in actual field usage means that contaminant caught by the filter can be released back into the fluid stream. One or more factors are the cause: media pleats, backing material, or any other structure or support in the filter can underperform under stress. Theoretically, the new standard will make filter specifications more accurate and, in turn, equipment will operate more efficiently.”

ISO/NWIP 23369 in Practice

The ISO committee includes members of major oil filtration manufacturers, a major reason the need for additional testing is recognized. No manufacturer wants to be accused of making filters that seem less efficient than advertised, which can happen when current approved filters operate under stress.

ISO developed this cyclic flow multi-pass test procedure for hydraulic filters to supplement the basic steady-state flow test of ISO 16889 for filter elements that will be used in cyclic flow environments. Using an industry survey and a round-robin laboratory testing procedure, ISO 16889 guidelines recommend a more stringent flow-rate cycle of 0.1 Hz, although it also notes that if much higher cycle rates are expected in actual service, “the test should be conducted at that frequency to produce more meaningful results.” However, only values resulting from testing at 0.1 Hz will be recognized.

Multi-pass tests using a cyclic flow rate require operators to choose a cyclic ratio of current change normally between 2:1 or 4:1. These ratios will stay consistent throughout testing and offer a one-step-closer approach to real-world filter performance results by showing the shedding of particles (slough) from filters being tested during current changes in the test fluid. The new standard suggests that flow rates (measured in lpm) change every 5 sec. at a 4:1 ratio.

Just as importantly, the test requires fine dust (smaller than 1 micron) vs. the medium dust (5 µm or larger) required by ISO 16889. The 5-sec. changes and varying rates means it’s possible that twice as much data can be recorded, although the data is averaged instead of exact.

What Does a New Standard Mean for You?

Everyone who uses filtration expects it to protect costly equipment, and minimize downtime and unexpected costs. Our international standards are in place to guarantee a certain level of quality and performance. Because of that, our standards need to be constantly evaluated to stay in line with current technology and equipment use.

Other than the obvious benefit of more efficient and reliable filtration, the primary benefit of this new standard for end users and equipment manufacturers is fewer surprises. Whether for equipment design or actual application, the purchase of a filter comes with a certain trust that comes from the certification on the label. A filter has to reliably capture and retain contaminants. If it can’t capture contaminants of a specific size at a specific efficiency, it cannot be relied upon. But retention capacity is as important as efficiency, if not more. If the filter is cleaning fluid efficiently but has no room to retain the contaminants, ironically, it can become a damaging source of contamination.

Which brings us back to cyclic flow. In current lab testing, the flow rate is constant, not taking into account that equipment at work can send fluid through a filter at varying rates. If not equipped to handle these varying rates, the filter becomes less efficient, and its capacity can be reduced. If a user expects 100-g contamination capacity, the filter must hold 100 g.

Some filters currently on the market meet the current standard in every possible way. The standard just isn’t good enough, so unexpected failures are happening. It’s often not the filter’s fault; it’s just being held to a standard that makes it seem more effective than it is. If enacted, ISO/NWIP 23369 will go a long way toward assuring users that they’ll receive a level of performance they expect from their filters, all other things being equal.

John Aune is hydraulics product manager at Donaldson Co., Minneapolis. For more information, visit www.donaldson.com.