Major hose manufacturers offer standard products spanning a wide array of sizes, pressure ratings, and durability. Most offer hoses with inner tubes that can handle different types of hydraulic fluids. A variety of hose covers that stand up to temperature extremes and abrasion are also readily available. And even though the hoses conform to industry standards, most manufacturers offer hoses that exceed standards—especially bend radius.

To gain an idea of what hydraulic hoses are available, read the following capsule descriptions.

Spiral Hydraulic Hose Targets High-Pressure Apps

Tuff Spiral flex hydraulic hose is engineered for high-pressure hydraulic applications up to 6,235 psi. Designed for applications with minimal space, it provides bend capacity of 8¼ to 9½ in., depending on the hose diameter selected. It comes in diameters of ¾, 1, and 1¼-in. ID,. Reinforced internally with four spiral layers of high-tensile steel wire braid, the hose has a durable oil, ozone, and abrasion- resistant synthetic outer cover. Impulse tested for up to 1 million cycles, it withstands temperatures from –40 to 250° F and meets flame-resistant MSHA designation.

Abrasion-Resistant, High-Pressure Hose

Diehard DF2D hose has highly abrasion-resistant cover combined with two braids of high-tensile steel wire reinforcement for high working pressures and impulse life. The hose is especially well-suited for applications requiring a compact outside diameter and tight bend radius. The hose meets or exceeds the requirements of EN 857 Type 2SC, ISO 11237 Type 2SC, and SAE 100R16 and comes in seven sizes from ¼-to 1-in. ID. Diehard hose complies with flame- and electrical-resistance (anti-static) requirements of Australian Standard AS 2660 and Methods of Test AS 1180.10B and 13A. It also meets flame-resistant designations of US MSHA.

Flame-Resistant Hydraulic Hose

Alfogomma Flexor spiral hydraulic hoses are available in sizes from ¼ to 2 in. Four-wire −12 is rated for maximum working pressures from 17.5 to 28 MPa (2,500 to 4,000 psi) and minimum bend radius of 5 to 25 in. (127 to 635 mm). Four-wire 4SP is rated for pressures of 28 to 45 MPa (4,000 to 6,550) psi, with minimum bend radius 6 to 13.5 in. (150 to 340 mm). Four-wire 4SH is rated for maximum working pressure of 25 to 42 MPa (3,650 to 6,000 psi), with minimum bend radius of 11 to 27.5 in. (280 to 700 mm). Four- or six-wire −13 is rated for maximum working pressures of 35 MPa (5000 psi) and minimum bend radius of 9½ to 25 in. (240 to 635 mm). All meet flame resistance acceptance designation.

Constant Working-Pressure Hose

Series 187 hydraulic hose, expands range of GlobalCore family for maximum working pressure of 1,000 psi (7MPa). The 187 Hose fills a gap at the lower end of our constant working pressure hose range and can be used as a high-pressure return line or to address an application where other hoses would be excessive. Constant-pressure hose simplifies selection by basing specification on pressure, not construction. Converting from various product lines to a singular hose family that provides constant working pressure across sizes leads to reduced inventories, lower maintenance costs, and less downtime.

Parker Hannifin Corp., Hose Products Div.

Flexible High-Pressure Hose

X Fight 4000 hose is rated for max working pressure to 4,100 psi and has half the bend radius defined by SAE 100 R12 (EN 856 R12). X Fight 5000 hose is rated 5,100 to 5,500 psi with half the bend radius defined by SAE 100 R13. X Fight 6000 is rated 6,100 psi with half the bend radius defined by SAE 100 R15. All three come in seven sizes from 3/8- to 1½ in. ID. Testing exceeds 1,000,000 impulses at 1.33% working pressure for 3/8- to ¾-in. sizes and 1.2% working pressure from ¾- to 1½-in. sizes.

Hydraulic Hose Tolerates High-Pressure Pulsations

EFG6K hydraulic hose is designed for high-pressure, high-impulse applications such as hydrostatic transmissions. With a max working pressure of 6,000 psi, EFG6K hose is compatible with biodegradable and standard petroleum-based fluids. Available in 121- through 200-ft continuous lengths. Available with standard or MegaTuff cover which lasts up to 300 times longer than standard hose during hose-to-hose and hose-to-metal abrasion tests per ISO 6945.

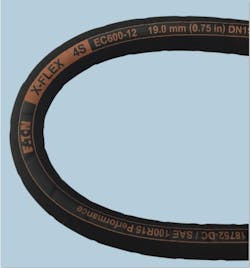

High-Pressure Hose Has Small Bend Radius

Designed for high-pressure applications, EC600 X-FLEX hose features a bend radius half that of SAE 100 R15. Hose is tested to more than one million impulse cycles at pressures to high as 6,100 psi. Offered with four- and six-spiral wire construction, it is rated for operation at temperatures from –40° to 121° C. with no fluid leakage between hose and fitting when the machine shuts down and the system cools.