If a hose or tube in a fluid power system will be connected and disconnected more frequently than once a week, then chances are a quick-acting coupling will pay for itself rapidly by improving productivity. Although simple in concept, many quick-acting couplings are precisely engineered for specific fluid applications. Their widespread use over many years has yielded a diverse variety of designs to serve not only specific, but general industrial applications as well. Consequently, uncertainty can arise as to whether a specific deign is best for a given application.

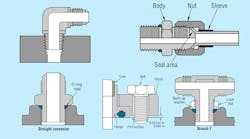

Regardless of the manufacturer, all quick-acting couplings have some elements in common. All have two parts: a plug and a socket. The plug is the male half and the socket is the female half. When connected properly, these parts seal and lock the joint effectively to contain internal pressures and resist any tensile forces that tend to pull the joint apart. The parts are easily disconnected without tools by disengaging a locking mechanism and separating parts.

Where they're used

The more frequently hoses must be connected and disconnected, the more valuable quick-acting couplings become. They also become more critical as machine productivity increases.

One common application is in assembly workstations, where a worker may have to rapidly switch from impact wrench to drill to riveter. With one quick-acting coupling half on every tool and the mating half on the air line, tool changing is accomplished in seconds. Without the couplings, separate air lines would be needed for each tool; the mass of tools and lines would clutter the workstation and could slow down production.

On hydraulic test stands, quick-acting couplings eliminate bottlenecks by slashing the time required to test each assembly. Just a quick push/pull, and the assembly is ready to test. In contrast, testing time would skyrocket if technicians had to tap into systems using fittings and a wrench for each test procedure.