Download this article in PDF format.

In a hydraulic cylinder, the pressure imparted by hydraulic fluid against a piston is converted to a force, which then performs the useful work. Because this force is transmitted by the piston rod, it must be dimensioned so that the stress of the rod (force/cross-sectional area) is low enough to minimize any risk of failure.

The forces in piston rods can be “push,” corresponding to a compressive stress in the rod, or “pull” (tension), which is associated with rod tensile stress. These forces are usually axial and uniformly distributed over the rod section.

If the rod is side-loaded, either deliberately or inadvertently, then bend forces may occur and the resulting stresses can be very high. Consequently, most designers of hydraulic cylinders will strive, insofar as possible, to avoid side loading. With single-acting cylinders, the piston rod is usually loaded in push-only mode so that fatigue is not an issue. In these instances, the dimension of the rod must be designed whereby its axial stress remains below levels that give rise to buckling.

Buckling is a sudden, large, and unstable lateral deflection. It can be associated with only a small increase in compressive load above a critical level, known as the buckling load. The corresponding stress can be far less than the yield strength of the rod material. Once it occurs, buckling leads to instability and collapse of the piston rod. This is why buckling in “failure mode” is potentially highly dangerous and may result in serious accidents.

Fatigue and Fatigue Testing

Double-acting cylinders feel alternating push-pull (compression-tension) loads. So, in addition to the risk of buckling on the compression part of the load cycle, cylinder designers must also consider the possibility of fatigue. Fatigue is a damage process whereby cracks are initiated and develop under repeated variable stresses that are much less than the tensile strength of the steel in the rod.

Apart from the mechanical characteristics of the steel chosen for a piston rod, other key factors for fatigue strength are surface finish, stress concentrations, and, for welded rods, weld quality. Piston rods that fail by fatigue inevitably do so either at the thread roots or at fillets, points at which the stress is greater due to reduced section and stress concentration effects, or at welds. All welds contain defects that can initiate fatigue cracks.

Hydraulic cylinders are usually fatigue-tested by locking the piston rod and subjecting it to load cycles via the appropriate pumping of oil. These load cycles can be push-pull (compression-tension) or only pull (so-called “pulsating tension”). A typical acceptable test result is that the rod has not failed after a stipulated number of cycles with a well-defined load/pressure maximum.

Generally speaking, the failure pressure corresponds to a given number of cycles—or, alternatively, the number of cycles that initiates failure at a given pressure—and increases in relation to the tensile strength of the steel in the rod. This is certainly true when fatigue cracks start from threads or fillets, but is less clear for weld-initiated fatigue failures that typically correlate with weld quality.

Improving Buckling Strength and Fatigue Resistance

Very often, increasing the yield strength of steel in a piston rod can enhance security against buckling. According to the classical Euler prediction, apart from dimension and shape, when a material is loaded axially and subjected to compression, its resistance to buckling increases with elastic modulus.

It has long been known that Euler accounts reasonably well for buckling loads of slender bodies—essentially elastic buckling. However, it greatly overestimates buckling resistance when there is less slenderness and plasticity comes into play.

This factor is recognized in building construction codes both in Europe and North America. These codes more closely scrutinize yield strength and elastic modulus of bodies having lesser slenderness.

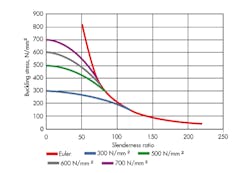

In Figure 1, for instance, the buckling stress of piston rods (calculated by buckling load divided by cross-sectional area) is calculated according to the method stipulated by the American Institute for Steel Construction (AISC). This is plotted against the slenderness ratio (the ratio of the length of a column and the least radius of gyration of its cross section). For a circular section, this equates to 4Le/D, where D is the diameter and Le the effective length. Figure 1 also includes the Euler curve for comparison.

Figure 1 confirms that the Euler description overestimates the buckling stress of rods with slenderness ratios of less than about 100. By this rule, yield strength plays an important role: Higher strength indicates a greater resistance to buckling, which is certainly the case in many instances.

For example, when the slenderness ratio for a 50-mm-diameter rod with 800-mm effective length is 64, its buckling resistance is close to being doubled if the yield strength of the base steel increases from 300 to 700 N/mm2. Here, the geometry of piston rods is such that yield strength does indeed influence buckling resistance. Nevertheless, Euler can adequately estimate the buckling behavior of rods with slenderness ratios over approximately 100.

Meanwhile, the European Convention for Constructional Steelwork (ECCS) gives a recommendation for estimating buckling stress in the elastic-plastic regime and predicts results that differ only marginally from the AISC method. Figure 1 more or less depicts the influence of yield strength as per the ECCS description.

Resist Buckling with Smaller Rod Diameters

Ovako’s Cromax 180X is a hard-chrome-plated bar based on a medium-carbon microalloyed steel. Because Ovako controls the entire manufacturing process, it is able to implement a great deal of control over minor alloy additions. Specifically, the company can optimize these processes to imbue the base steel with high strength while maintaining a strong analysis of overall waste management.

If we compare the properties of the Ovako Cromax grade with C45E, a common steel selection for piston-rod applications, we can see that C45E has a minimum yield strength of 305 N/mm2, while the minimum yield strength of Cromax 180X is 500 N/mm2. The high level of yield strength for Cromax 180X can also be guaranteed in the finished (i.e., chrome-plated) condition.

If we assess what this means for buckling, again looking at the data in Fig. 1, it is apparent that when applying the appropriate regime of slenderness ratio, piston rods made from higher-strength Cromax 180X will exhibit better resistance to buckling than corresponding rods based on C45E steel.

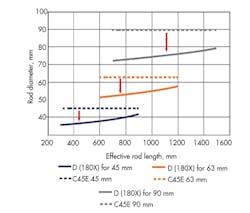

Furthermore, for a given effective length, the diameter of a Cromax 180X rod can be reduced in relation to a rod of C45E while maintaining the same margin of safety against buckling. This is demonstrated quantitively in Figure 2, which depicts the potential diameter decrease when rods of C45E steel are swapped for Cromax 180X versions. In Fig. 2, downsizing is given as a function of rod length for three different diameters in accordance with ISO diameters: 45, 63, and 90 mm.

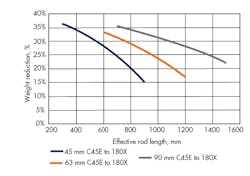

Naturally, the reduction in diameter also reduces the weight of the rod. This corresponding percentage weight reduction relates to the downsizing illustrated in Fig. 2, and is shown as a function of effective length in Figure 3.

Potential for Cost Reduction

Apart from the clear benefits of weight reductions in piston rods, the cost of the piston rod’s materials will drop. The following example illustrates the potential for cost savings: A piston rod in C45E steel, with a 63 mm diameter and 1000-mm effective length, is replaced by a rod in Cromax 180X with diameter 55 mm. This reduces weight by 5.8 kg, or 24%. This example shows that Cromax 180X may be up to 24% more expensive than chrome-plated C45E, yet still remain a better economical proposition.

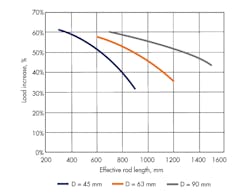

Another perspective is that, if a rod of C45E steel is replaced by a Cromax 180X version with the same diameter, then it can transmit a greater load while keeping the same margin of safety against buckling. This is illustrated in Figure 4, again for the ISO diameters 45, 63, and 90 mm.

Of course, to enjoy the benefits of such an increased load rating, a major redesign of the cylinder will be necessary… and that may not always be feasible.

Predicting Conditions for Fatigue Failure

Ovako has developed a model to predict the conditions for fatigue failure in piston rods as initiated from thread, fillets, and other “changes in section” that define stress-concentration factors. The model also takes in a detailed account of surface finish and size effects.

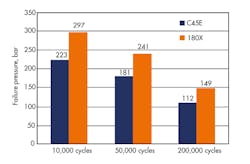

Predictions from this model, for fatigue failures initiated at threads in push-pull mode (stress ratio equals –1), are shown in Figure 5. The model assesses 45-mm-diameter rods, 80-mm-diameter cylinder bore, and ISO M33 × 2.0 thread. The results are presented as the failure pressure corresponding to three different fatigue lives—after 10,000, 50,000, and 200,000 cycles of pressure reversal—and show the calculated improvements of Cromax 180X over C45E.

Fig. 5 shows that the higher 750-N/mm2 minimum tensile strength of the steel in Cromax 180X is capable of better fatigue performance than rods made of the conventional-grade C45E with minimum tensile strength 590 N/mm2. Here, we can draw a parallel with buckling: A stipulated fatigue resistance is achievable using a smaller diameter rod, with positive outcomes in both weight and cost.

Welding and Machinability

With enhanced steels, it is essential to ensure that improved characteristics are not gained at the expense of vital processing characteristics such as weldability or machinability. This is prioritized when Ovako applies its specialized steel manufacture and analysis control to Cromax 180X.

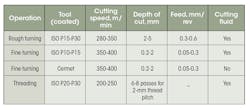

Cromax 180X is found to have equivalent or better machinability compared with hard-chrome bars based on C45E steel, in spite of the fact that the latter’s strength and hardness are considerably higher. More details are listed in Table 1.

Given that the manufacture of piston rods often involves welding, the weldability of the steel chosen is a crucial characteristic—second perhaps only to machinability in terms of importance. Cromax 180X is found to be somewhat easier to fusion-weld than C45E, and has been optimized for friction welding. Through analysis and specialized manufacturing processes, the steel is designed to minimize risks for failure that may result from brittle areas in the heat-affected zone (HAZ) of friction welds.

Hardenability

For applications that may suffer damage to the piston rod due to external impact, it is useful to examine a particular steel’s hardenability. Ovako designed the metallurgy of Cromax 180X to be characterized as medium-carbon content in order to achieve a high surface hardness that offers strong resistance to external impacts in tough working conditions.

For piston-rod applications requiring extremely high strength, Cromax 180X can also be offered in a cold-drawn execution with a minimum yield strength of 690 N/mm2. That is on par with quenched-and-tempered low-alloy steel with considerably higher alloy content (e.g., grade 42CrMo4).

In Table 2, the steel in Cromax 180X is compared with other grades commonly encountered in hydraulic piston-rod applications. These include C45E, the low-carbon steel 19MnVS6, and 38MnVS6, a medium-carbon microalloyed steel with elevated manganese content.

Summary

We have examined how detailed research into the behavior of steels in relation to buckling for hydraulic piston rods has led to the development of a new steel grade, Cromax 180X by Ovako. In hard-chrome-plated execution, Cromax 180X is characterized by higher strength than the traditional grades used for hydraulic-cylinder piston rods.

Improved yield strength means that piston rods can be downsized without compromising the margin of safety, thus protecting against buckling under axial compressive loads. This brings benefits in both weight and cost. The resistance to fatigue failure under reversed or pulsating pressure cycles also improves thanks to higher tensile strength.

Erik Bohman is the managing director of Ovako Cromax, Hallstahammar, Sweden.