In ancient times, cheesemaking was a way to preserve milk products and bridge gaps in the food supply. Today, cheese is not only a staple but often a luxury, with overall sales and the growth of specialty varieties continuing to expand. While the basic process of cheesemaking begins by curdling milk and then separating the solid parts from the whey, each type of cheese has its own characteristics, determined by the type of milk it is made from and the way it is processed and aged.

Cheesemaking requires five major steps: curdling, heating, forming, fermentation, and ripening. An important part of the process is pressing to separate the milk solids (curds) from the liquid (whey). In small dairies, this operation still is done manually or mechanically, but for large-scale production, it now is being automated, using pneumatic cylinders and valves.

Before forming the cheese, pneumatic cylinders are used in a pre-pressing operation to exert pressure on a large plate above the curd. The plate may be perforated to allow the whey to escape as pressure is applied. Pneumatic cylinders excel at controlling the pressure. “Pneumatics truly shine here,” says Gerson Henning, dairy expert at Emerson’s AVENTICS, says. “Both the applied pressure and application time can be set with extreme precision.” The maximum pressure applied to the curd is only about 0.71 psi (50 g/cm2), so close control is a necessity.

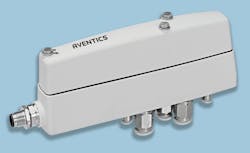

aventics cclSeries CCL pneumatic cylinders are hygienically designed for food plant applications such as cheese manufacturing.

During forming, the application speed and pressure are adjusted to the cheese variety being produced. Higher application pressures produce harder cheeses, but pressure must be applied gradually, since a higher initial pressure compresses the surface layer and seals in moisture.

Large cheese presses may be equipped with several hundred pneumatic cylinders, such as the AVENTICS Series ICS, suitable for air pressures up to 145 psi and temperatures between –13 and 158°F. A high-temperature version, rated up to 248°F, also is available. These hygienically-designed stainless steel cylinders feature smooth surfaces, interlocking seals, and cushioning screws, and use a non-toxic food-grade lubricant.

Henning points out that, on the large presses, several hundred of these cylinders often move extremely large plates. Pneumatic cylinders also are included in other parts of the system, where they perform functions such as moving the cheese during the course of its ripening.

Valves that control the cylinders must meet the same hygienic standards. A typical example is the AVENTICS Clean Line CL03 series. Designed to meet the IP69K high-protection class, they resist high-pressure water and steam jet cleaning. Their high-tech polymer composition is resistant to cleaning agents and aggressive chemicals, making them suitable for applications in wet areas and under harsh conditions—no protective cabinet needed. They provide flexibility, with the ability to generate up to 32 different pressure stages in a single system. Valve manifolds can be configured online quickly, which provides a unique part number, full documentation, and 2D/3D CAD files. Standard CL03 valves (up to 8.8 CV) and CL03-XL valves (up to 1.1 CV) can be combined on the same valve manifold, with choice of multipin or fieldbus connectivity.

Hundreds of pneumatic cylinders are used in some cheesemaking operations, providing the controlled pressure needed for consistent quality.

Automating a Tradition

A typical example of how pneumatic technology is taking backbreaking work out of the traditional cheesemaking process can be found in the Po River region of Italy, where Grana Padano and Parmigiano-Reggiano cheeses have been produced for more than 800 years. Bringing automation to the process is Progema Engineering SrL, of Borgo Virgilio, Italy. The company, which specializes in designing and manufacturing innovative dairy and cheesemaking equipment, has developed the Forma4 machine, which replaces manual forming and turning of the Gran Padano and Parmigiano-Reggiano cheese wheels.

The machine is built to meet the food industry’s cleaning-in-place principle, which describes cleaning of equipment without disassembly and with minimal operator involvement. It incorporates corrosion-resistant, double-acting cylinders from the AVENTICS ISO Clean Line (CCL) series to close the round molds and ensure that the whey is pressed out by applying the appropriate pressure. Later in the process, when the cheese wheels are turned during aging, the cylinders keep the mold under the proper tension.

The cylinders are available in designs that meet ISO 15552 and ISO 21287 standards. They feature a smooth profile to minimize pocket areas that can collect dirt and contaminates and are designed to handle high-pressure washdown applications. Their head, cap, tube, and tube face are all made of anodized aluminum.

Although often mounted as an integrated group, CL03-EV valves are placed directly on the pneumatic cylinders they regulate in the Forma4 machine.

AVENTICS CL03-EV single inline valves regulate the cylinders on the Forma4 machine. Because of their IP-69K protection, hygienic design, and NSFH1 lubricants, Progema Engineering can install individual valves directly on the actuators instead of in a remote protective cabinet. This allows the compressed air lines to be shorter, which minimizes dead volumes and pressure losses and also reduces air consumption. This modular concept also allows the Forma4 machine to be used for further automation.

In the production of Grana Padano and Parmigiano-Reggiano, the machine is used on the first day to remove the excess whey and form the cheese shapes. Further along in production, the cheese is immersed in brine for 21 days, followed by seasoning in the last phase. During these operations, it is necessary to turn the cheese wheels periodically. They weigh approximately 88 l. (40 kg), and the machine now turns these wheels automatically, eliminating a monotonous, heavy-duty task.

During the month-long aging period, cheese wheels have to be turned regularly. Progema Engineering developed a sophisticated, fully automatic turning device to do this using pneumatic cylinders, which are visible near the bottom of the machine.

By incorporating pneumatic technology, the Forma4 machine is easily adaptable to the many variations in the cheesemaking process, of which there are as many varieties as there are types of cheese. Cheese can be made of milk from cows, goats and buffalo, as well as other animals (reindeer, for example).

The various types of cheese are differentiated by their proportions of water and fat content. The greater amount of dry matter a cheese contains, the harder it is. For example, Parmigiano-Reggiano and Gran Padano are considered hard cheese, with a dry matter content of at least 60%, while soft cheeses such as feta or camembert will have a dry matter content of about 35.

For more information on pneumatic, electromechanical, and control solutions for food and beverage equipment, click here.