The Old Timer of Royal Oak, Mich., was a regular contributor to H&P years before we ever even heard of the internet. But most of his advice is just as ueful — and interesting — today.

So rather than leave his wisdom printed on pages archived in our storage room, I pulled out issues from the late 1980s and early 1990s and have been reproducing relevant entries in this blog. Here is my 16th entry, which was originally published in the April 1989 issue:

Seeing is believing

However, we had some production people who had seen and remembered that 100-psi note and used it as a ready-made excuse for every production slowdown — air pressure is too low. They caught the ear of the management team with this and the order came down, “Get the air pressure on that line up to 100 psi quickly and make sure it stays there!”

We knew there were a lot of things we could do to improve that air system, be we also felt there was no real urgency to any of them. My boss decided to buy some time for this project.

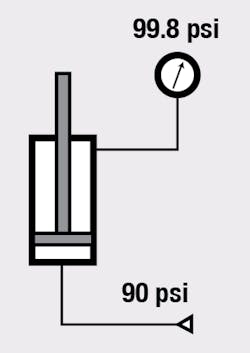

His method: replace all the air gauges on that production line with new liquid-filled pressure gauges. Install a short 1-in bore cylinder with 5/16-in rod between the line and the gauge. Connect system pressure to the cap-end port; connect the gauge to the rod-end port after filling that end of the cylinder with oil.

We now had a little pressure booster in each path to the gauges. Ignoring friction, 90 psi in the system generated 99.8 psi in the annulus end of the cylinder, and that’s what the gauge registered. The production people now could see that they had the 100 psi they thought they needed, and they had to look for other cures for production problems while we worked on the air system at a more leisurely pace.