The Old Timer of Royal Oak, Mich., was a regular contributor to H&P years before we ever even heard of the internet. But most of his advice is just as ueful — and interesting — today.

So rather than leave his wisdom printed on pages archived in our storage room, I pulled out issues from the late 1980s and early 1990s and have been reproducing relevant entries in this blog. Here is my 15th entry, which was originally published in the March 1989 issue:

Two-way Intensifier Squeezes Sand

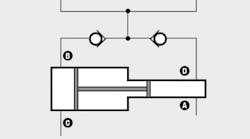

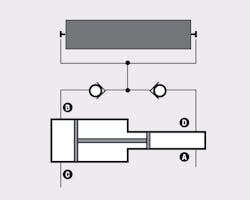

We didn't have pumps with the pressure or flow capacity to drive the ram like that, so we combined two 10-ft stroke cylinders — one with a 16-in. bore and one with an 8-in. bore —onto a common piston rod to create a 20-ft long, 2-way intensifier.

The pumps that were available could supply 100 gpm at 1000 psi. Applied at Port A, this flow and pressure pushed 400 gpm at 250 psi out Port B for rpid travel. When the pump flow was applied to Port C, we got 25 gpm at 4000 psi from Port D to generate the squeezing force. We had a 4:1 flow multiplier in one stroke direction, and a 4:1 pressure intensifier in the other.

The complete circuit to control the press was fairly complex, but it consisted mainly of small pilot valves operating larger pilot-operated check valves. This made it easy to maintain.