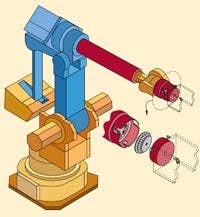

Expensive or delicate end tooling for robots requires protection against crashes when the robot accidentally bumps into something during set-up or in production situations.

The conventional solution installs a spring clutch between the robot wrist and the end tooling. In this mechanism, a series of die springs holds two plates in the same position relative to each other. One plate is bolted to the robot, the other carries the end tooling. If the end tooling inadvertently strikes an object, the springs provide flexible compliance between the plates and an electric switch stops the robot.

However, the spring clutch must be adjusted to meet the requirements of every different application. This involves tightening or loosening bolts to change the compression on each spring. The trick is to get the springs tight enough to keep the clutch from nuisance-tripping during normal operation, but not so tight as to prevent the robot from shutting down before totaling your $15,000 one-of-a-kind end tooling.

In practice this involves first overtightening the springs, then repeatedly running the robot through its expected motions as you gradually back off the tension. Because tension can only be adjusted while the robot is stopped, this procedure can be laborious, time-consuming, and error-prone.

Our Collision Isolator, using a Firestone Airmount air spring, produces an elegant alternate approach. A #16 air spring in a simple housing provides the force necessary to maintain position between the robot and its end tooling. The air spring is compliant in every direction, assuring quick response in the event of a crash. The Collision Isolator’s force can be easily adjusted in precise increments using an external pressure regulator — even while the robot is moving. The chance for accidental over-adjustment is minimized. Also, the trip force can be quickly reduced when teaching the robot (the time when the chances for collisions are greatest).

The air spring also permits quick tool changes — allowing one robot to use several end tools, or to drop off a malfunctioning end effector and install a back-up. Simply set the tool down; apply a slight vacuum to the actuator to deflate it, rotate the robot wrist, slip the shoulder screws through their key slots, and slide the tooling plate off.