Condition monitoring in vacuum generators helps users monitor and optimize cycle times, helping ensure reliability and prevent machine failures.

With the OVEM vacuum generator, from Festo Corp., users have a choice of three performance classes and numerous models with different functionalities. All models have an integrated air-saving function.Ensuring reliability

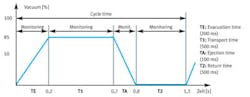

Designed to provide measurements against a setpoint entered by the user, the OVEM vacuum generator can detect a slow or sudden leak or any deterioration in the evacuation time for vacuum buildup. The master value is the cycle time, which represents the speed of a handling operation and, thus, the productivity of an installation. OVEM will prevent machine failures and downtime by taking action before they occur, such as through preventive maintenance. Diagnostic criteria can be set to more or less stringent values for specific applications. The modular design allows reconfiguring assemblies as needed.

An easy-to-read LCD with additional barograph (with choice of modes) enables continuous status monitoring of a complete vacuum system. An integrated solenoid valve controls the compressed air supply. This valve can be operated as normally open (no vacuum generation) or normally closed (as a safety function with vacuum generation). An integrated non-return valve prevents the vacuum from collapsing.

Simple design saves time

The vacuum generator and ejector pulses are controlled by two integrated solenoid valves. Short tubing lengths ensure fast switching times. A regulating screw adjusts flow of the ejector pulse.

For information, click on the “Vacuum Selection” software tool available in the Festo digital catalog from www.festo.com.