Good fluid-power design has always balanced system performance with factors such as package size and overall cost. And thanks to advanced materials, engineering software, and sophisticated modeling tools, leading component manufacturers offer a wide range of mini and micro-pneumatic products. This lets OEMs and users reduce the size and weight of a system without sacrificing flow or output force. Smaller size generally equates to energy savings and longer life, compared to more-conventional products. And miniature components typically cost less and are easier to install. Here’s a look at some recent innovations.

Safe and clean valves

The Oxygen Clean series electronic valves from Clippard Instrument Laboratory Inc. measure only 1.56 in. long and 0.87 in. in diameter. They are designed for use with oxygen applications and will work with air and inert gas. They are available in 2-way or 3-way, normally-closed, or fully ported, and use a patented valve system that ensures quick, quiet, and consistent results.

They accept low-voltage and low-current signals and convert them into high-pressure pneumatic outputs. With a low power consumption of only 0.67 W, a response time of 5-to-10 msec, and voltages of 6, 12, or 24 Vdc, these valves offer unlimited flexibility in design.

The valves are ultrasonically cleaned, assembled, inspected and tested in an enclosed controlled area with a state-of-the-art positive pressure High Efficiency Particulate Air filtration system. All organic and inorganic contaminants, such as particulate matter and Hydrocarbon oils are removed. No organic sealants, adhesives, or lubricants are used during manufacturing to ensure oxygen clean service.

Clippard electronic valves are rated for 28 in. Hg vacuum and pressures to 105 psig.

Mini solenoid valves

MH1 miniature solenoid valves from Festo are for in-line or sub-base mounting. The poppet valves offer flow rates of 14 lpm in the 2/2-way version and 10 lpm in the 3/2-way unit. The mini valves can link together via a pneumatic multiple-connector plate or electrical multi-pin plug. There is also the option of horizontal electrical connections on top and underneath, and connections for mounting on a PCB are available.

Response time of the valves is an impressive 4 msec. This makes them suited for electronics manufacturing, light assembly, the medical and semiconductor industries, and wherever compact and fast-switching valves or pilot valves are required. Working pressure is to 8 bar, and vacuum service is also possible. The 10-mm wide valves weigh only 10 gm and are rated protection class IP40.

100 million cycles

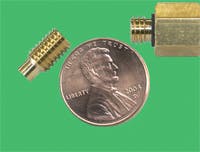

Norgren’s smallest air valve is called Chipsol – measuring only 19 mm long by 8.5 mm diameter – and it’s used with lubricated and unlubricated compressed air, neutral gases, and for fluid control. According to the company, it is well suited for applications that require compact size, light weight, and low energy consumption. Chipsol is reportedly ideal for controlling pneumatic or medical micro components, as well as portable equipment and other industrial applications.

Pressure rating is 0 to 8 bar and the devices are available with various pneumatic mounting patterns that adapt to most industrial requirements. Chipsol can also mount to manifolds with a common supply and exhaust, but individual outlets. Features include high flow, low electrical power consumption, cycle rates to 6000 cycles/minute, and extreme reliability – with life exceeding 100 million cycles. The direct-actuated, spring return cartridge valve is made of stainless steel.

Proportional control

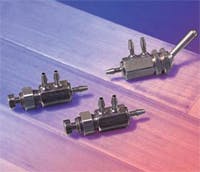

The LS-V05C proportional pneumatic control valve from Enfield Technologies is a 5-port, 4-way valve designed for in-line or manifold mounting. A bidirectional linear force motor and spool-and-sleeve combination ensure the valve precisely follows a command signal. It features response time of only 2.5 msec, low hysteresis, and high linearity.

The valve is for pneumatic systems that demand position, force, or pressure control, and fast switching. Typical applications include laboratory test and measurement, industrial automation, animatronics, and medical equipment.

Minimizing pressure loss

The new IMH 832 Series Side Exit Chek Valve from the Lee Co. is said to provide the lowest pressure loss of any valve this size. At only 8 mm in diameter, the valve features a side exit design which permits flow in excess of 6 gpm of water at 100 psid.

The valves feature low leakage, easy installation, and robust stainless steel construction, and are typically used in industrial hydraulic applications such as off-road equipment. The 832 Series Side Exit Chek Valves are 100% tested to ensure consistent, long term performance.

Multi-purpose valves

Series 58 valves, manufactured by Peter Paul Electronics, are constructed of stainless steel or polyester with standard nitrile and optional fluorocarbon seals. The valves are suited for air and other common gaseous media and used in portable medical devices, analyzers, portable test equipment, and similar applications.

Stainless- steel models come in 2-way and 3-way versions. Six molded-plastic models include 2-way, NO and NC; 3-way, NO and NC; directional control; and multi-purpose. They’re available with either 10/32 ports for stand-alone operation or a manifold mounting base, and come with wire leads or European-style micro-DIN connectors. Sizes are as small as 2.00 1.37 0.63 in.

Miniature and high flow

Pneumadyne’s Sub-Micro valves are said to offer a higher flow rate than most other subminiature valves currently available. A flow rate of 2.9 scfm at 125 psi results in a Cv of 0.04. A versatile design lets the 3-way valves be plumbed as normally closed or normally open, in addition to accommodating vacuum applications. Metal actuators enhance an overall robust design. And a detented toggle offers roller-ball-like actuation that typically means less wear and longer product life. Flats on the threaded neck ensure the valve does not rotate when panel mounted. Electroless nickel plating provides corrosion resistance and a clean appearance.

7-mm valve

SMC Corp. of America has released the new Series S070, a 7-mm wide, 3-port solenoid valve and manifold that can be used to operate small bore cylinders or as a pilot valve for air-operated valves. The standard valve consumes 0.35W and only 0.1W with a power-saving circuit, and generates operating noise 38 dB.

A standalone version is available with body-ported or base-mounted configuration. The manifold version comes with a maximum of 20 stations and is available with barb fitting to accommodate 3.18 and 4-mm diameter tubing as well as M3 and M5 ports. S070 valves can be used with air, inert gas, and vacuum (133 Pa) and Cv varies from 0.006 to 0.021. The valves handle various operating voltages and have an IP40 enclosure rating.

Sub-micro solenoid valves

Spartan Scientific’s Series 2510 sub-micro 2-way and 3-way solenoid valves are suited for applications when size restrictions limit the use of larger valves. With 1.0 or 1.5-mm orifices, the 2510 gives users a range of flow possibilities at various pressures to maximum 120 psi. Flow factors are 0.04 Cv for a 1.0 mm orifice and 0.08 Cv for the 1.5-mm orifice. Response time is 18 msec for a complete cycle, and the 2.4-W power consumption makes it a good combination for programmable controller applications. The unit includes an aluminum body with 10- 32 ports, brass/stainless armature assembly, and a glass-filled nylon encapsulated coil that rotates 360°. Through-holes in the body permit convenient panel mounting.

High vacuum, low footprint

PIAB Vacuum Products has introduced the P2010, a multistage ejector vacuum pump suited for applications requiring light and reliable part handling, such as electronics production, pharmaceuti ca l processing, and auto manufacturing. The uni t stands only 1.08 in. high and weighs just 0.54 oz. While most pumps require at least 59 to 87 psi, the P2010 generates a vacuum of 24.9 in. Hg at feed pressures of only 26 psi, reducing compressed air costs by up to 50%. It also produces higher vacuum flow than other traditional singlestage ejectors. Unlike electric pumps, ejector pumps do not generate heat and, thus, need no cooling. And the unit’s small size eliminates the need for rigid mounting, making it easy to install. The P2010 works with feed pressures to101.5 psi, but this excess capacity is not normally needed.

Lightweight vacuum generators

SBP Series vacuum generators from Schmalz, available with integrated valves and sensors, are suited for decentralized vacuum generation on high-speed gripper systems for material-flow and handling processes. The compact and light housing is made of impact-resistant plastic, and the generators are available with single nozzles with diameters of 0.5 to 2.5 mm. T h i s lets users match size to the application for quick response and energy savings. Threaded or plug-in connectors simplify installation. Users can also combine several ejectors to form so-called ejector blocks, which can be controlled either centrally or locally.

A built-in vacuum sensor permits system monitoring, thus ensuring safe gripping of the workpiece without the additional cost and hassle of external sensors and connections. The ejectors can also be equipped with valves to control suction and blow-off functions.

For more information:Clippard Instrument Laboratory Inc., 7390 Colerain Ave., Cincinnati, OH 45239, (877) 245-6247, www.clippard.com/oxygen-h Bosch Rexroth, 1953 Mercer Rd., Lexington, KY 40511, (859) 259-3852, boschrexroth-us.com/brp Enfield Technologies, 41 Monroe Tpke., Trumbull, CT 06611, (203) 459-0700, enfieldtech.com Festo Corp., 430 Wireless Blvd, Hauppauge, NY 11788, festo.com/usa The Lee Co., P.O. Box 424, Westbrook, CT 06498, (800) 533-7584, leeimh.com Nason, 1307 S. Highway 11, Walhalla, SC 29691, (800) 229-4955, nasonptc.com Norgren, 5400 S. Delaware St., Littleton, CO 80120, (303) 794-2611, norgren.com/usa O’Keefe Controls, P.O. Box Q, Trumbull, CT 06611, 800- 533-3285, okcc.com Peter Paul Electronics, P.O. Box 1180, New Britain, CT 06050, (860) 229-4884, peterpaul.com PIAB USA, 65 Sharp St., Hingham, MA 02043, (800) 321- 7422, piab.com Pneumadyne, 14425 23rd Ave. North, Plymouth, MN 55447, (763) 559-0177, pneumadyne.com Schmalz Inc., 5250-150 Old Wake Forest Rd., Raleigh, NC 27609. (919) 713-0880, schmaltz.com SMC Corporation of America, 10100 SMC Blvd., Noblesville, IN 46060; (317) 688-0132, smcusa.com Spartan Scientific, P.O. Box 9792, Boardman, OH 44513, (330) 758-8446, spartanscientific.com |