D’Zhana Simmons was only 14 years old when she and her parents learned earlier this year that she needed a heart transplant. D’Zhana and her parents later flew from their home in Clinton, S. C. to Holtz children’s Hospital in Miami for a transplant operation.

Unfortunately, the newly transplanted heart didn’t work properly, so doctors were left with few options. They decided to implant a dual ventricular assist device (VAD) into D’Zhana’s chest to keep her alive until a new donor became available.

It worked. The blood pumping system took the place of her natural heart for nearly four months, at which time she underwent a second heart transplant procedure.

D’Zhana’s story is unusual because she is so young to have gone through such an experience. However, VADs have been implanted into thousands of patients to keep them alive for extended periods. Many of these life-saving devices are powered by pneumatics. This should come as no surprise, considering the cushioning effects that are easily achieved with compressed air and the high reliability of the technology.

The marvel of pneumatics

Our natural hearts consist of four chambers — left and right atria, and left and right ventricles. The right ventricle pumps blood to the lungs, and the left ventricle pumps it to the body. The left ventricle has to work the hardest, so when it can no longer pump blood to the body effectively, a heart transplant may be an option.

VADs have proven to sustain life for weeks or months — either to help a patient’s weakened heart recover from surgery or for bridge-to-transplant periods. But what’s important to the patients is the quality of life these portable devices allow. That is, patients are able to recover at home and carry on most of their normal activities.

Pneumatics to the rescue

For more than 30 years, Thoratec Laboratories Corp., Pleasanton, Calif., has been developing and manufacturing advanced medical technologies to improve patient survival and quality of life. Its Implantable VAD is the only implantable biventricular support option for advanced heart failure patients requiring months or years of support, and Thoratec’s VADs are the first and only biventricular support systems approved for home discharge.

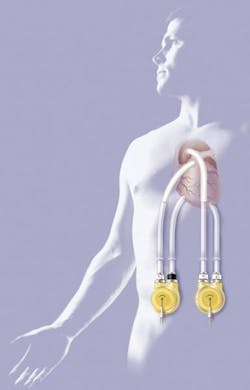

Thoratec’s Implantable VAD consists of three main components:

• blood pump, which takes the place of one or both of a patient’s ventricles,

• TLC-II pneumatic driver, which consists of an air compressor, controls, valves and other components, and

• cannulae, a network of tubing that routes air between the blood pump and pneumatic driver.

Lee said that from the compressor, air or vacuum is routed to accumulators (left pump, right pump, vacuum) that each store a quantity of compressed air or vacuum. This stored energy serves as a reserve to allow disconnecting different drivers to suit the particular situation. The accumulators also stabilize pressure to eliminate the pulsations inherent to the compressor.

Valves provide long life

Not surprisingly, pressure requirements are low; the left ventricle typically requires maximum pressure of only 200 to 250 mm-Hg (3.87 to 4.83 psig), the right ventricle requires 120 to 170 mm-Hg (2.32 to 3.29 psig), and vacuum is 0 to –50 mm-Hg.

From the accumulators, air is routed to a series of normally closed poppet valves provided by Humphrey Products. According to Humphrey’s Dale Dratt, Thoratec uses a custom engineered version of Humphrey’s model 320 valves, which are direct-acting, solenoid actuated poppet valves.

Dratt said that Thoratec had been using different valves, but wanted to increase their rated life to 5 million cycles or more. He explained that the model 320 valves are normally rated to 20 million cycles, but Thoratec’s testing showed them to exceed 100 million.

Into the patient

Lee continued that from the pneumatic drive, air travels to the patient through about 5 ft of ¼-in. flexible tubing. The air then flows into or out of the blood pump. Lee explained, “There is only a single pneumatic lead (tube) connecting the blood pump to the driver, where the air is shuttled between positive and negative pressure (vacuum) to help assist the blood sac (pump) during filling and ejection.”

The main component of the pump is a blood sac. Blood flows into this sac and is pushed out by the pump. Biomedical quality check valves ensure that blood only flows into the sac during filling, and only flows out during ejection.

Lee continued, “The air from the pneumatic driver does not contact the blood sac directly. Instead, a diaphragm separates the air chamber in the pump from the blood sac. So in the unlikely event that the diaphragm is compromised, there still is a safety barrier to prevent air from getting into the blood sac. The diaphragm and blood sac are both made from our proprietary, polyurethane-based polymer that can endure several million cycles of deflection needed to support patients for several years.”

Versatile control

Lee explained, “The Implantable VAD has two operating modes that affect the pump rate. The first is fixed mode, which would be set by a clinician through a touchscreen that communicates with the TLC-II driver. The internal controller board then commands the solenoids to open or close valves for positive and negative pressures for every beat to fill or eject the blood in the pump. This rate is in the 70-80 bpm range for most patients.

“The second operating mode is Auto mode, which is preferred. A sensor in each pump detects when the blood sac has become filled completely. The sensor signal passes to the TLC-II Driver (via a cable from the pump to the driver), at which point the controller board knows that the pump is full and instructs the solenoids to stop passage of vacuum to the pump, and allow positive pressure to initiate sac ejection.

“As the patient exerts himself or herself, the cascade of events in turn produces greater filling pressures to the heart, which causes more blood to flow to the blood sacs, so they fill faster.

The sensor detects more rapid complete filling and initiates the next pump ejection cycle. This causes the driver to increase the pump rate automatically to accommodate the physiologic needs of the patient automatically. If the patient rests, less pressure is generated to the pump, so the driver rate will automatically slow down.

For more information on Thoratec, including videos and patient testimonials, visit www.thoratec.com.

For more information on Humphrey’s line of products, services, and engineering capabilities, visit www.humphrey-products.com.