Multifunction hydraulic cartridge valves simplify machining, take up less space, and cut installation time.

Hydraulic screw-in cartridge valves allow condensing the majority of a machine's hydraulic controls into a single Hydraulic Integrated Circuit (HIC) or incorporating valves into the body of other hydraulic components, such as cylinders. This reduces the installation time and space requirement while improving serviceability and performance.

A new range of screw-in, multifunction, cartridge valves has been introduced by Integrated Hydraulics, Mentor, Ohio. Ordinarily, some HICs become very intricate, but these new multi-function valves fulfill the roles of two or more cartridges, thereby simplifying systems.

Designated 4CKKT50, the valves incorporate dual pilot-operated check valves with thermal relief. They can reduce the number of cartridges in a circuit, simplify machining of components, minimize demands, cut assembly time, and reduce the number of potential leak paths.

Dual pilot checks typically are built into the end caps of stabilizer cylinders. Conventional valves require three cavities and a series of cross-holes. Integrated's cartridges will hold stabilizer legs in both extended and retracted positions, with the relief element preventing thermal expansion of hydraulic fluid from over-pressurizing the cylinder.

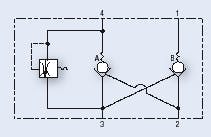

As shown in the schematic, each pilot section of a dual-pilot check valve is cross connected to the opposite line, giving automatic pilot operation in both directions. Pressure at port 3 opens poppet B, allowing flow from port 1. Likewise, pressure at port 2 opens poppet A, allowing flow from port 4.

The direct-acting relief valve, at left in the schematic, controls flow between ports 3 and 4. When pressure in port 4 rises above the setting of the relief valve, the relief valve opens, allowing flow to port 3, thus relieving pressure on the cylinder by opening poppet A.

The 4CKKT50 cartridge is rated to 300 bar and has a flow rate of 25 lpm, making it ideal for small to medium stabilizer cylinder applications. Internal leakage past the

poppet valves is 0.3 ml/min in one line and 0.5 ml/min in the other. It fits into the same cavity as Integrated's series 5 solenoid valves so no additional tooling is required.

For additional information, call Integrated Hydraulics at (440) 974-3171 or visit www.inthyd.com.