Maintenance was called and found that the valve’s 10-24 mounting bolts broke off close to the sub-plate but they did not find damage to the base. They were able to remove the broken bolts and found all the parts. (The parts must not have tasted like peanuts!) The modules seemed to be reusable but, importantly, the D03 directional valve was damaged and needed replacement along with the stacking bolts.

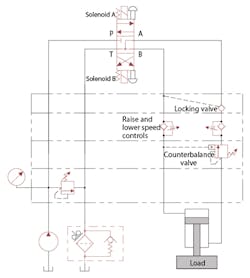

The directional valve was a 3-position, float-center, solenoid-operated D03 size with finger operated manual overrides. The manufacturer offers an option that extends the manual operator, covers them with a flexible waterproof boot, and can easily be shifted with a finger. A new valve and bolt kit was ordered and installed. Everything seemed to be working fine electrically, but the valve could not be shifted manually.

They returned the valve for warranty repair, and the distributor sent them a temporary replacement that did not have manual overrides. Much to their surprise, the warranty claim was denied. They were told the valve worked fine and no problem could be found.

The report indicated that the valve and manual overrides worked well. They reinstalled the valve and experienced the same problem with the overrides. It didn’t make sense that it would work electrically but not with the manual overrides. The overrides could not be moved or shifted manually. What should they do next? Can you figure out the problem?

Robert J. Sheaf, Jr., is the founder of Certified Fluid Consultants (CFC) and President of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology. Visit www.cfc-solar.com for more information.

Find the Soluiton

If this problem piqued your curiosity, and you’d like to see how it was resolved, refer to this column in our November issue. We’ll print the solution then. However, if you don’t want to wait a full month to learn about the solution, visit fluidpowertalk.blogspot.com. We’ll post the solution there!