Today’s electrohydraulic proportional valves are smaller, lighter, and with quicker response than ever. However, communication from a joystick or other input device or an electronic control to the valve requires a driver. Whether the driver is digital or analog, its cost can eat up a substantial portion of a project’s budget.

Sometimes there’s no getting around the cost of a driver. If motion must follow a variable input signal or be coordinated with other axes, a traditional proportional valve driver is in order. However, if direction and speed will be controlled by a human operator or a PLC, then a control using simple on-off inputs can be a cost effective alternative.

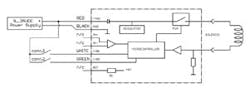

The RH-0608 proportional valve driver from Copley Controls, Akron, Ohio, uses a pair of simple two-pole switches as inputs to a PWM processor to provide a driving signal to a proportional valve. In addition to the pushbutton input, the driver also accommodates signals from a radio control or from a PLC.

The RH-0608’s control algorithm allows two digital inputs (contact closures) to run a typical proportional valve in lieu of an analog input. It is this two-contact concept for which Copley Controls has received a provisional patent.

Copley Controls has provided radio controls for overhead cranes, locomotives, and other types of equipment for decades. Dave Perrine, general manager, explains, “When trying to apply some brands of radio remote control to a mobile machine, the analog input issue would come into play.” Consequently, the original intent of the RH- 0608 was for radio-controlled mobile equipment that needed a smaller transmitter than the joystick (belly box) transmitters typically used for analog input to the proportional valve.

Perrine continues, “Variable frequency drives (VFDs) on cranes can be controlled by analog belly box transmitters, but most operators don’t want to carry around a 4- to 7-lb transmitter. Therefore, the digital ports (contact closures) of the drive are used to control the VFD that moves the crane or other equipment, so you can use a smaller handheld transmitter.

Optional PLC control

The RH-0608’s digital interface can be fitted on a valve as a single channel driver or be packaged as a single or dual channel driver and panel mounted.

Perrine explains, “We’ve also found interest in using this in factory automation because a PLC often has extra digital contacts that could interface to an RH-0608. Otherwise, the system integrator might have to purchase an analog module for several hundred dollars and write the software to control the analog module. The RH-0608 has a small menu that can be scrolled through, and settings are made with a screwdriver.”

Simple operation

Referring to the illustration, when Contact 1 is closed, output current will ramp up to a preprogrammed low-speed setting; opening Contact 1 ramps output back down to zero. With Contact 1 closed, closing Contact 2 causes output current to ramp up; keeping Contact 2 closed long enough causes output current to reach a maximum- speed setting. Opening Contact 2 before max speed is reached holds output current constant at that midrange level. Thus, the RH0608 produces infinitely variable output from two digital inputs.

For more information on the RH-0608 proportional valve driver, call Copley Controls at (330) 666-8174, visit copleycontrols.net, or e-mail [email protected].