Throughout the latter part of the 20th Century, people dreamed of the day that airplanes would be as ubiquitous as automobiles. From the Jetsons' fantasy of rush hour in mini-spaceships to the occasional Popular Mechanics article about how to build a flying car, the images persisted. While the dream is not yet a reality in 2006, a interesting new step in that direction is on the horizon.

The newest buzz in aviation is the emerging Very Light Jet (VLJ) market. Over the next five years, the VLJ market is estimated to be worth $2.52 billion, according to a study by U.K.-based consultants PMI Media. Six key VLJ programs are underway, including the Cessna Citation Mustang (the first to receive FAA certification), Eclipse 500, Embraer P100, and the HondaJet.

In addition, a much-anticipated VLJ air-taxi market is beginning to take shape with many operators placing orders and gearing up for the start of service in the Eastern U.S. and Europe. VLJ fractional ownership companies are already being formed in California and Canada, foretelling the fact that the era of the VLJ is about to begin.

One of the leading contender platforms in this race, Figure 1, is the Embraer Phenom 100 — and hydraulic power is playing a big part in the platform's successful development and performance. The Phenom 100 is already under construction, with first flight scheduled for the first half of 2007. Certification of the $2.85 million twinjet is currently planned for mid-2008.

The Phenom 100 will accommodate up to eight occupants and is powered by Pratt & Whitney Canada's PW617F engines, each with 1615 lb of thrust. With four occupants, it has a range of 1160 nautical miles (IFR) or 1320 nautical miles (VFR) and a maximum operating speed of Mach 0.7. The aircraft is designed for short field takeoff performance and is capable of flying at 41,000 ft.

Hydraulics are on board

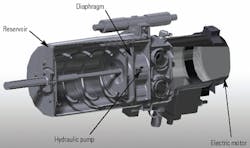

The Embraer VLJ hydraulic power generation system is being designed and developed by Eaton Corp.'s aerospace business. It consists of a hydraulic power unit, Figure 2, accumulator and accumulator charge gauge, and valve. The system is designed to provide the required hydraulic power to operate the landing gear and brakes.

The hydraulic power unit is a fully integrated hydraulic system with a dc electric motor, hydraulic pump, reservoir, manifold, filters, and valves. The integrated power unit contains all the essential components of a typical hydraulic system within a single, multi-functional, and lightweight package.

As with all aircraft, system weight and volume are critical factors in its overall design. The hydraulic power unit consists of a fixed displacement hydraulic gear pump with a nominal rating of 1.1gpm at 3000 psi. The pump is designed to shut down when the pressure reaches approximately 3000 psi, to maximize pump and motor life and minimize heat generation. The brush-type 28-V dc electric motor, chosen due to the cost constraints of the program, is rated at 2.65 hp at 7500 rpm. Thermal reset protection is included in the motor design.

John Halat, Eaton Fluid Power's chief engineer, noted, "An integrated hydraulic power pack approach for the Phenom 100 offered Embraer a considerable weight savings. In addition, in order to minimize system downtime, we engineered all of the individual components in the power pack to be twice as reliable as the customer specified."

Mauro Amano, Embraer's landing gear and hydraulic system team leader, said, "Light weight, compact size, and high reliability are definitely the main constraints for selecting motion control components for small jets. With the Phenom 100, low power consumption and low noise generation are also important design criteria. Eaton's hydraulic power unit was selected for the Phenom 100 because our analysis showed it was the best compromise between performance, weight, dimensional envelope, operational history, and cost."

Eaton is also providing a spring-pressurized rolling diaphragm reservoir in the hydraulic power pack. This design not only maximizes diaphragm reliability and life but also reduces the overall system weight. The system manifold is located between the electric motor and the pump/reservoir and contains all the control valving to support the system.

Additional systems packages being designed and developed by Eaton for the Phenom 100 include the aircraft's electromechanical flap system and landing gear control hydraulic components.

What's next?

Embraer is also developing the Phenom 300 jet, which will be configured to accommodate up to nine occupants. It will be powered by two of Pratt & Whitney Canada's PW535E engines, each with 3200 lb of thrust. Its range with six occupants on board will be 1800 nautical miles (IFR). This aircraft will be capable of flying at 45,000 feet at Mach 0.78. Details on the Phenom 300's hydraulics are not yet available, so watch for details in the future.

|

Find out more on the rolling diaphragm Look for more information on Eaton's rolling diaphragm reservoir in next month's Ideas & Applications department. |