When hydraulic tube ends must be joined, fittings or flanges are widely used because they allow disassembling and reassembling the connection. When a permanent joint is needed, brazed or welded connections generally have been the method of choice because the joint remains leak free, even when continually subjected to shock and vibration inherent to many hydraulic systems. Now, however, system builders can opt for a technique that offers the many advantages of a welded joint without requiring the preparation and skill of welding.

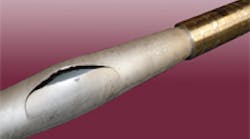

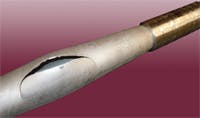

Pyplok fittings, from Tube-Mac Industries Ltd., Stoney Creek, Ontario, rely on a non-welded, 360 radial swage method for joining tube and pipe sized from ¼ in. to 3 in. rated for pressure to 9000 psi. As the photograph shows, fluid pressure exceeding the burst pressure of a tubes will rupture at the tube instead of the Pyplok joint.

The swaging action used in installing Pyplok fittings is controlled by the tooling, producing a reliable, leak free, and permanent connection that will stand up to the stringent demands of the hydraulic system. This method eliminates the problem that traditional hydraulic system connection methods suffer from in that they are prone to leakage caused by continuous vibration and pulsation.

Because it involves a cold mechanical process, the system does not have to be purged and cleaned prior to making a connection. The need for fire permits, fire watch personnel, non-destructive testing (radiography), and system cleaning from welding are all eliminated. Pyplok fittings will increase plant uptime, while eliminating the rework and leaks from traditional tube and pipe connection methods, saving valuable time and money. Installation can be performed by any employee following a very short training period.

For more information, call Tube-Mac Industries at (877) 643-8823 or visit www.pyplok.com.