Higher speeds, increased pressures, reduced reservoir size, the need for higher production output and longer fluid life, as well as environmental concerns, all play a role in the continuing trend for more durable hydraulic fluids. So you may wonder if your fluid will continue to provide the protection your system needs.

Higher working pressures lead to higher operating temperatures, which may increase the oxidation rate and thermally stress fluid. Smaller reservoirs have multiple effects. Entrained air doesn't escape, foam doesn't break up, water doesn't separate, contaminants don't settle out, and the fluid doesn't cool. Fluids are the life blood of a system. The industry must keep up with the demands on systems and fluids that keep them running.

Durability study

A fluid's anti-wear durability is essential for successful operation. One of the best ways to determine durability is to take the standard pump tests and push them to the limit — by extending their length or running them at higher temperatures or in the presence of contaminants. The goal is for the fluid to continue to protect the pump from wear over its rated service life. Our durability tests show that the premium hydraulic fluids provide the durability for long, service-free performance.

There is no industry test method to measure the effects of increased stress on fluids. Current test methods involve short-duration pump testing coupled with laboratory bench testing. In this study, we used widely accepted pump tests, including the Denison T5D vane pump, the Eaton-Vickers 35VQ25 vane pump, and the Sundstrand Series 22 piston pump tests.

Although all of these tests successfully predict wear characteristics of a fluid, they suffer from relatively short test duration or low temperature. As a result, they only measure the presence or absence of an anti-wear additive in the fluid.

We drained used oil and submitted it for evaluation in standard ASTM bench tests to determine performance retention. We used the Denison HF-0 specification bench test protocol because it evaluates most aspects of hydraulic fluid performance.

The fluids used for this study included multigrade and monograde formulations that were blended with good quality Group I base stock. The hydraulic package selected for this study was added at the recommended level. The multigrade fluid contained a shear stable viscosity modifier.

Sundstrand test — When we ran a Sundstrand piston pump test under standard conditions (180° F, 225 hr, 5000 psi, and 3100 rpm), it passed all manufacturer-established criteria. When we ran it a second time under standard conditions — but doubled the time to 450 hr — it also passed.

The Sundstrand pump test includes 1% water contamination to further stress the fluid. Even with added contamination, there was no evidence of hydrolytic instability or filter plugging problems related to water contamination.

We ran the test a third time at an elevated temperature of 250° F. Because of the higher temperature, we added no water to the test; however, all other conditions remained the same. The samples still passed the series of tests.

We concluded that the hydraulic fluid based on the premium anti-wear formulation had the durability to exceed the performance parameters of the Sundstrand piston pump without a problem.

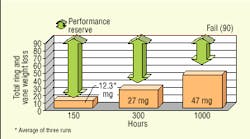

Eaton-Vickers test — The next phase involved running an extended-length Eaton-Vickers 35VQ-25 vane pump test to determine the durability of the anti-wear formulation. We ran the test at standard test conditions of 200° F, 3000 psi, 2400 rpm, and a flow rate of 38 gpm. By increasing the time limit from the standard 50 to 1000 hr, we saw progressively more amber to dark brown varnish deposits in the reservoir as the test progressed from 500 to 1000 hr.

The Eaton-Vickers specification calls for measuring the ring and vane loss of the pump after running for 50 hr. Our result, depicted in Figure 1, shows less than the 90 mg acceptable weight loss for total ring and vane wear. We concluded that the antiwear formulation had the durability to exceed the parameters of this test.

Denison test — The final phase of pump testing used the Denison T5D vane pump run under standard test conditions to generate the used fluid needed to complete the retention of durability part of the study.

Bench tests

After pump testing, fluids were drained and run through many of the standard ASTM-established performance bench tests used to evaluate fresh hydraulic fluid. These tests included ASTM D943 oxidation testing, D4310 1000-hour sludge tests, and D2619 hydrolytic stability testing. Standard tests included D665 rust test, D892 foam, D1401 demulsibility, and others.

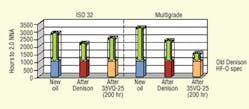

The D943 oxidation test predicts relative oxidation life of hydraulic fluids. Because of the enhancement of new base oils, Denison no longer requires ASTM D943 as part of its approval process. In the past, Denison required 1000 hr minimum. Today's oils exceed that requirement easily. Our study, with results charted in Figure 2, shows that even after the stress of the EatonVickers' 35VQ-25 vane pump test, the premium hydraulic fluid continued to provide excellent oxidation life, with only a small decrease in D943 turbine oil stability test life vs. new unstressed oil.

Even after undergoing the stress of the pump test, the used monograde and the multigrade fluid passed the D2619 hydrolytic stability test. This ensures that the additive package has not reacted with water to form insoluble sludge or excess acidity, nor did it demonstrate any other physical changes that could interfere with the fluid's ability to perform properly.

After pump testing, the product continued to meet the requirements of the Cincinnati Machine thermal stability test (D2070), indicating excellent stability of the anti-wear additive used in the formulation, as shown in Figure 3. The stresses of the Denison and Eaton-Vickers vane pumps did little to negatively impact the thermal stability of the premium hydraulic fluid used in our study.

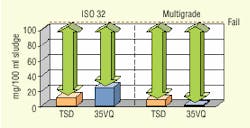

The D4310 1000-hr sludge test determines sludging characteristics of hydraulic fluids. Not all hydraulic additive packages offer sludge resistance or thermal stability of the product we tested, and not all hydraulic additive packages will provide clean systems for long-life. Results of the product we tested indicated that although some increase in sludge is seen after running a T5D or 35VQ pump test, the resultant sludge is well within the test limits (11.3 and 59.3 mg for monograde, respectively; 27.1 and 109.2 mg, respectively for multigrade) of 200 mg.

Our study also shows that durability is retained in key areas such as rust protection, demulsibility, and anti-foam characteristics.

Contact the authors at dave. [email protected] or robert. [email protected] or phone (440) 943-4200.