In most applications, it is preferable to stop a moving load through controlled deceleration. Elastomeric bumpers, compression springs, and dash pots sometimes are used to accomplish this by absorbing energy. Bumpers and springs decelerate by storing energy as compression, and releasing it results in a rebound effect. A dash pot is a fluidfilled cylinder with an opening through which fluid may escape at a controlled rate. Any force acting against the piston in the cylinder encounters high resistance from the fluid at the beginning of the stroke, then much less as the piston retracts.

The problem is, none of these methods dissipate the energy uniformly. The impact of a moving load against a resisting force produces peak forces that are transmitted to plant equipment, or to the load itself. In order to dissipate the energy uniformly, a shock absorber is required.

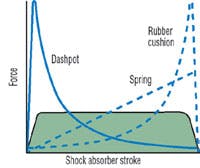

Figure 1 shows plots of force vs. stroke for the same load moving at the same velocity striking a rubber bumper, a spring, a dash pot, and a shock absorber. The kinetic energy to be absorbed is the same in each case, but it is accepted at differing rates. A linear rate of deceleration is the most efficient combination of force, space, and time that can be used to stop a moving object. The ideal rate is an almost square curve, where a constant force resists the load, until it is slowed to a stop.

Linear deceleration

Shock absorbers convert the kinetic energy of a load into heat which is dissipated into the atmosphere. They stop a moving load with no rebound and without transmitting potentially damaging shocks to equipment.

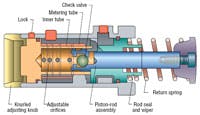

In its most general form, a shock absorber consists of a double-walled cylinder with space between the concentric inner and outer walls, a piston, some means of mechanical return for the piston, and a mounting plate. The piston return is usually a spring, which can be mounted externally around the piston rod or internally on the inside of the cylinder body. The cylinder is filled with fluid; all air is bled from the fluid because air bubbles cut the efficiency of the shock absorbers by causing spongy or erratic action.

Orifices are drilled through the inner cylinder wall at exponential intervals. The reason for the exponential spacing is because of the exponential relationship between speed and kinetic energy:

EK=12 mv2.

where EK is kinetic energy, m is mass to be decelerated, and v is the velocity.

When a moving load contacts the shock absorber’s piston rod, it moves the piston inward, forcing fluid through the orifices in the inner cylinder wall. The fluid is forced through the oil return passages, into the space behind the piston head. As the piston moves inward, it closes the orifices behind it, reducing the effective metering area, and maintaining a uniform deceleration force as the load loses its energy.

Fluid pressure is constant in a shock absorber, providing constant resistance to the load. The load slows to a stop as its kinetic energy approaches zero. No rebound occurs because the shock absorber stores no energy.

Several events must occur before the piston rod can return to its fully extended position. First, the load must be removed from the piston. The spring then will push the piston outward, opening a check valve, which permits fluid to flow from behind the piston to the space where the piston was in its retracted position.

Fixed vs. adjustable shocks

The two basic types of shock absorbers have fixed or adjustable orifices. The fixed type, sometimes referred to as non-adjustable or self-compensating, has orifices drilled along the inner cylinder wall at distances determined by the manufacturer. Although generally less expensive, they are designed for a wide range of application loads. They are best suited to highly automated applications, where the exact operating parameters will not change significantly over time.

Adjustable-orifice shock absorbers can accommodate a range of loads — as much as 30 times the range of a nonadjustable type. They are adjusted by moving a graduated dial on the outside of the shock absorber. This moves a ring around the orifices to control the size of the openings, Figure 2.

Controlling the amount of fluid forced through the orifices controls the deceleration rate. The dial rotates through 90° or 180°, and some designs up to 270°. It may be calibrated on a scale from 0 to 9 or 1 to 10. Usually, the higher the number, the greater the resistance to impact.

Adjustment generally is made by observing energy absorption at different settings. Constant resistance to load should be evident throughout the stroke of the shock absorber.

Orifice design

Orifice design is critical to the operation a of shock absorber. A circular hole drilled in the inner cylinder wall will permit fluid to flow to the outer portion of the cylinder, but causes pressure drop or a change in fluid viscosity due to change in fluid temperature. A simple hole will produce laminar fluid flow, which is less efficient in dissipating energy and often cannot be controlled precisely.

As a shock absorber cycles more and more frequently and if there is a high proportion of laminar flow through the orifice, operating temperature will increase and the resulting change in fluid viscosity requires constant readjustment of the shock absorber. A knife-edge orifice is very short when compared to the thickness of the inner cylinder wall. This produces turbulent flow that is not sensitive to changes in fluid viscosity, and is easily controlled.

Selecting a shock absorber

When choosing a shock absorber, considering the type of load to be stopped is most important. Basic types of loads encountered in shock absorber applications include pure inertial, free-falling, rotating, and loads subject to an additional propelling force. Load weight and velocity are the next two most important factors in sizing a shock absorber. Additionally, potential shock to equipment, number of impacts per unit of time, and ambient conditions must be considered to properly select a shock absorber.

Application conditions include extreme temperatures, load acceleration, maximum propelling force applied to the load, or time limitations imposed on the equipment. Time limitations would include minimum and maximum cycle times and the time required for the shock absorber to return to the extended position between strokes.

Cycle rate is another important consideration. If the shock absorber must handle too many impacts within a given time, it will overheat, resulting in poor performance and premature failure. Rapid cycling may heat the fluid, reducing its ability to dissipate energy.

As a safety feature, most manufacturers recommend that shock absorbers be sized for 70 to 80% of capacity. Because the amount of impact the shock absorber can accommodate is inversely proportional to the length of its stroke, doubling stroke length will cut the impact of the load in half.

Most shock absorber manufacturers offer sizing software to assist in accurate selection for any application.

Mounting

Shock absorber mounting methods vary depending on the application and space availability. Selected mountings include front and rear flange, sidefoot, clevis-type, and lock nut. Stop collars can be added to help prevent the shock absorber from bottoming out at the end of its stroke. Many of today’s models include integral stops built into the design of the shock absorber.

Shock absorbers must be attached rigidly to a non-flexing mounting structure. Mounting can be achieved through a drilled hole and secured by a mounting stop collar, rear mounted into a drilled and tapped blind hole and secured by a jam nut, or via its own mounting flange.

Applications

Shock absorbers can be used in a myriad of places. Applications include straight line functions, as well as rotary, free-falling, rolling, and sliding movements.

Miniature series versions of shock absorbers are commonly used in small linear slides, material handling and packaging equipment, small robotics, medical equipment, and instrumentation. Moderate sizes find application in automobile manufacturing and production machinery, conveyors, packaging and glass bottling equipment, rotary actuators, and large robotics. Large bore series shock absorbers can be found in foundry, steel, marine, lumber, and other heavy equipment industries.

One common situation for shock absorbers is on high-cycle automation machinery that uses rotary motions to save time and space. In this instance, the shock absorbers should be positioned near the pivot point to provide ample clearance for the work area. However, this placement subjects the shock absorbers to high effective weight conditions due to their low velocity. Most of the kinetic energy involved originates from the propelling force rather than from inertia. For such applications, specify shock absorbers designated as high-cycle models, or those designed to operate in a velocity range from 14 to 2 ft/sec.

Portions of this article were excepted from the 2008-2008 Fluid Power Handbook & Directory.