Mobile equipment and off-road machinery that offer the latest electronic innovations, larger capacities, and ease of handling are of little use if they are too expensive to afford. Like most OEMs today, these equipment makers are looking to improve manufacturing efficiency and hold the line on costs. Their needs have sparked a growing interest in hydraulic couplings that not only eliminate leakage, but also improve accessibility and installation ergonomics, and reduce installation time, production bottlenecks, and equipment rework.

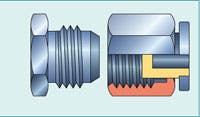

Figure 1. With threaded couplings, metal-to-metal contact forms a highpressure seal.

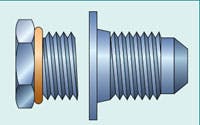

Figure 2. In O-ring couplings, the rubber-to-metal seal is more tolerant of over-tightening.

Figure 3. With quick-acting couplings, the male and female halves easily push together to form a leak-free connection.

Hydraulic coupling designs have advanced considerably over the years to improve performance and installation convenience, but the overall function of these components remains relatively unchanged.

Hose assemblies are attached with one of two techniques: threaded or threadless couplings.

Threaded couplings

Threaded couplings rely on metal-to-metal contact, while threaded O-ring type fittings contain pressurized fluid by compressing an elastomeric seal. In either case, tightening threads between mating halves of the fitting (or fitting and component port) forces two mating surfaces together to form a high-pressure seal.

The JIC hydraulic seal, the most common threaded coupling in use in the U.S. and the world, is popular among equipment designers because of its performance versatility, availability, and low cost. Threads on the JIC hydraulic couplings bring the male and female cones together, while the fit of the cones against each other forms the seal to prevent leaks at high pressures.

Metal-to-metal threaded seals can be prone to leakage because they are torque-sensitive — over-tightening distorts the threads and creates a path for leakage around the threads. Also, over-torquing couplings with metal-to-metal seals can result in thread stripping, a cracked swivel nut, or deflection or scratching of the cone seats that will prevent proper sealing.

Another popular threaded fitting is the O-ring type coupling. The O-ring on the male component is compressed against the corresponding female component and makes the seal. The rubber-to-metal seal in O-ring faced couplings and adapters leaves no distortion and is more tolerant of overtightening. In addition, O-ring couplings and adapters are much more forgiving in high-vibration, high-impulse, or high-torque applications.

However, installation of O-ring seals is more expensive because it takes more time and a higher level of skill to insert the rubber O-ring in the male fitting. Plus, more care is required to make sure the O-ring doesn't fall out or get damaged when the assemblies are connected.

Also, when an O-ring is part of the fitting, it is critical that the seal material is compatible with the type of hydraulic fluid being used. Even when the correct seal is used, circuit heat can deteriorate the seal over time.

Threaded metal-to-metal and O-ring couplings share two common flaws:

- First, they lack any visual indication that the correct amount of torque has been applied when making the connection. This can lead to high re-work time and cost on the production line, along with leaks and costly warranty claims.

- Second, threaded couplings reduce assembly line productivity. OEMs using threaded couplings report that it takes between 60 to 75 sec to hand-tighten and then torque down a standard hydraulic connection. Threadless couplings take 2 to 3 sec to make a coupling connection.

Threadless couplings

Threadless connectors are an alternative to threaded connectors commonly used in fluid power systems. The male and female halves simply push together — without wrenches or special assembly tools — to form a leak-free connection.

Manufacturers have introduced specially designed threadless connectors that yield the performance of O-ring seals, but eliminate the cost and O-ring assembly problems for fluid power systems with working pressures to 6000 psi. Threadless connectors provide a greater sealing performance over JIC and O-Ring connectors, but they don't have to be torqued-on to make the connection.

These fittings are called quick-acting couplings. They are used exclusively at the hydraulic port or manifold on steering units, valve blocks, pumps, and motors. For OEMs, they offer several key benefits:

- leak-proof connections that reduce the cost of warranty claims and fluid leaks from equipment used in stationary and mobile hydraulic platform applications,

- easier, quicker connections that result in manufacturing cost savings and increased productivity in the assembly process,

- a tactile positive feedback and visual confirmation that the connection has been made,

- assurance that connections can not be accidentally made with other threadless couplings,

- easy serviceability, and

- easy replacement in the field with traditional and widely available threaded couplings.

The biggest advantage of threadless couplings is the reduced time and expense needed to install hydraulic hose and tubing assemblies, and the improved accessibility to the hydraulic system.

Certain kinds of equipment, such as skid steers, are compact in design and have little room for the plumbing and routing of hydraulic sub-systems, which must be designed into tighter spaces where they are subject to heat build-up and other stresses.

Installations with conventional threaded fittings can take several minutes or even hours, and they are subject to leaks because of torquing inconsistencies and other variables. On the other hand, threadless couplings allow even confined, difficult-to-reach connections to be completed in minutes.

Instead of screwing on the threaded connector and tightening it with a wrench, threadless connecting halves — the male end and the female adapter — simply push together to form a leak-free connection. A clip ring positively engages the male and female halves, without any assembly tools. Some threadless coupling designs do require a special tool for removal, however.

|

Specifying clean hose assemblies Valves: Microscopic contamination can mill away tolerances, which are used for sealing purposes. On spring centering valves, debris may get caught between the valve and wall surfaces, slowing down the motion of the valve or causing sluggish or adverse mechanical actuation. If large contaminate particles are in the system, they may block critical lubrication passages. Debris could embed in soft bearing surfaces or severely impede the flow of fluid through tight channels. When abrasive particles enter the clearances between moving parts, they score and hone the surfaces to greater clearances. As these clearances broaden, system performance is compromised by pressure losses incurred due to fluid leakage from high to lower pressures. Even worse, particles that are greater than or equal to the orifice openings can become wedged between the surfaces. This may cause excessive wear or cause the system components to seize. Pumps and drives: Microscopic contamination can mill away tolerances, creating leak points. These leak points rob the system of pressure and cause poor responsiveness. By preventing and removing as much contamination as possible in hydraulic systems, pumps maintain higher efficiencies and last longer. System cooling: If passages do become blocked, working fluid may not flow through to remove contaminants generated from metal to metal contact. Lower flow rates mean greater heat buildup in systems and thermal breakdown of the working fluid. Blockage of fluid flow can result in "starving the pump," over-heating, and possible burning up the engine. Benefits of a clean hydraulic system

Contamination and hose assemblies |

Dennis Kemper is an application engineer with Gates Corp.'s Fluid Power Product Application Dept., Denver. Contact him at (303) 7444391 or [email protected]