Manufacturers of hydraulic cylinders made of conventional steels cannot guarantee against brittle fracture — and the inherent danger of personal injury and material damage — when the material is used at temperatures as low as –20°C (–4° F).

This situation led the VDMA ( Verband Deutscher Maschinen-und Anlagenbau — the German Engineering Federation) to form a working group made up of representatives from well-known construction equipment manufacturers and hydraulic cylinder and cylinder tube producers, with the aim of investigating the suitability of new materials for use at low temperatures. The results were developed in cooperation with the Department of Mechanical Engineering at the Ruhruniversitt Bochum and the Mannesmann Forschungsinstitut (Mannesmann Research Institute).

The use of hydraulic cylinders made of cold drawn, seamless steel tubing is critical at temperatures below 10°C, because multiple component failure cannot be ruled out completely at this temperature or lower. Systematic investigation of ready-to-install cylinder tubes, including impact tests and drop weight tear-tests (DWTT) verified these findings.

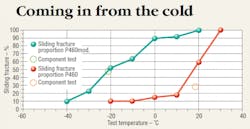

Because impact testing does not accurately reflect true component behavior, both tests were supplemented by component burst tests to simulate realistic operating conditions. The results of the DWTT and component tests match sufficiently with regard to the lowest tolerable operating temperature and correlate with impact tests. Therefore, a minimum impact energy value can be defined for the suitability of a material for use at low temperatures.

To prevent component brittle fracture, the corresponding standard required for materials currently used to manufacture cylinders — namely, E355 and P460 — has accelerated the development of modified material variants with the lowest impact energy value. Components made of the modified steel grades exhibit a sufficiently high proportion of ductile fracture behavior at temperatures as low as -20°C. Therefore, they possess enough plastic deformation reserves to reduce the danger of multiple component failure.

The graph above demonstrates this situation using the example of the P460 and P460 modified steel grades. (These are similar to ASTM A333 Grade 10, but with 0.20% maximum V, 0.40 to 0.70 % Ni, and 1.15 to 1.70 % Mn instead of the values stated for ASTM 333 Grade 10.) The modified material allows safe operation of hydraulic cylinders at temperatures as low as –20°C.

A further benefit is an increase in strength properties for some steel grades. This permits a wall thickness reduction of up to 30%, which, in turn, allows significant weight reduction.

Within the framework of the VDMA working group, manufacturers of mobile and crawler cranes have decided to maintain a level of impact energy that prevents brittle component failure. The first step is to require tube manufacturers to carry out impact testing of 27 joules at –20°C (with the notch position being longitudinal and transverse to the cylinder axis).

In conclusion, the newly-gained information about the burst behavior of hydraulic cylinders in lowtemperature conditions using different material concepts will lead to the use of modified material grades in the near future. This will not only prevent component failure at low temperatures, but offer a potential weight reduction of up to 30% as well.

This discussion was provided by S. Herzig and G. Junker, of Mannesmann Prazisrohr GmbH, Muheim, Germany. For more information, visit www.smp-tubes.com/english.