Digital electrohydraulic servoactuators represent an effective method of transmitting high force and velocity within an extremely compact and programmable linear actuator. They offer highly repeatable closed-loop control that can be configured to match the requirements of a wide variety of applications. These integrated smart cylinders are composed of:

• a low friction servocylinder with integral position and force transducers to produce smooth, controlled motion at both high and low speeds,

• a servoproportional valve equipped with on-board electronics to ensure tight control and fail safe operation in case of malfunctions, and

• integral digital driver, axis controller, and algorithms designed specifically for electrohydraulics. This combination ensures smooth, stiction-free motion at low speed without sacrificing maximum speed.

Digital servoactuators can provide an automation architecture based on distributed intelligence and fieldbus interfacing for direct integration into existing CANopen or PROFIBUS-DP communication networks. They can be configured slave control — which performs closed-loop motion control in real time according to external analog or fieldbus position reference signals — or motion cycle control — which carries out a preprogrammed position/time motion cycle via closed-loop control. The machine’s control processor only has to provide digital commands (start, stop, switch-over) to synchronize the servoactuator to the overall machine working cycle.

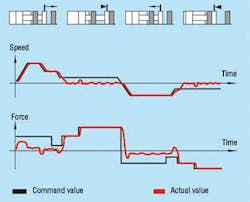

A position-force function allows a single device to manage both the motion and the force output of any electrohydraulic axis. The axis controller automatically defines which control is active according to the position, pressure, or force feedback from a load cell.

Atos original software, featuring intuitive and powerful graphic interface, allows the user to easily set and program the servoactuators in order to obtain best performances, improved diagnostics and customized motion profiles according to specific applications requirements.

For more information, visit www.atos.com.