Self-contained electrohydraulic actuators from M-Mac Actuators, Vancouver, B.C., Canada, combine the stiffness, speed, and high force of hydraulic actuators with the accuracy and reliability of electromechanical actuators in a compact, stand-alone package. The actuator is currently being used in thermal power applications, grain processing, machine control, aerospace hydraulics, power station flue dampers, and industrial HVAC.

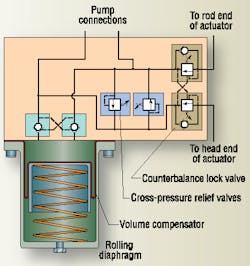

The actuator's closed-circuit hydrostatic drive is controlled entirely by its electric motor. Either ac or dc, the motor can have on/off control with a reversing starter, or variable-speed control through a frequency drive or inverter. When driven by a dc motor, variable speed can be achieved through an SLR controller. Turning the motor in either direction directly drives the fixed-displacement, birotational pump to create flow to and from the cylinder . . . causing it to extend or retract.

Different volumes

One design challenge is to compensate for the different volumes at the head and rod ends of the single-rod actuator. M-Mac does this with a spring-loaded expanding chamber attached to the circuit block and piped to the hydraulic circuit through pilot-operated check valves.

At commencement of the extension stroke, the volume compensator is fully charged with a volume of oil equal to at least the cylinder's differential volume. The volume demand at the blind end of the cylinder is greater than that which re-circulates through the pump from the rod end. To make up the difference, the pump is supplemented from the compensator through pilot-operated check valves. A signal from the pressure side opens the pilot check valve, permitting oil, under a nominal pressure, to supplement pump demand at the suction port. The compensator is sized so that surplus oil volume is still available when extension is complete.

As the retraction stroke starts, the greater volume of oil in the blind end re-circulates to satisfy the smaller volume demand at the rod end. Excess volume flows into the compensator through the opposite pilot check valve. After full retraction, the volume compensator is fully charged, ready to supplement pump flow during the next extension.

The circuit includes cross-pressure relief valves to limit pump pressure in both directions. Thermal expansion in the cylinder is relieved through thermal relief valves integral to the counterbalance lock valves. Increased oil volume due to thermal expansion again dissipates into the volume compensator through the pilot check valves.

A sensible solution

To offer a totally integrated force/ motion control package, M-Mac embeds Temposonics position sensors from MTS Systems Corp., Cary, N.C., in the cylinder. Temposonics sensors incorporate magnetostrictive technology to provide accurate and reliable linear-position sensing. In magnetostrictive sensors, the momentary interaction of two magnetic fields induces a sonic strain pulse in a specially designed waveguide.

A movable permanent magnet that passes along the outside of the sensor tube is the source of one field. The other field comes from an interrogation pulse of current applied along the waveguide. The resulting strain pulse travels at sonic speed along the waveguide until it is detected at the head of the sensor.

The sensor determines the position of the magnet by measuring the elapsed time between the initiation of the interrogation pulse and the arrival of the resulting strain pulse. Consequently, accurate non-contact position sensing is achieved with absolutely no wear to the sensing components.

External sensors can create installation challenges, but the Temposonics sensor fits right into the cylinder. The resulting selfcontained actuator is well suited to space-constrained applications. By enclosing the sensor in the cylinder body, no dust and dirt can enter and gum up the position indicator. This configuration also protects the sensor from physical damage or ambient contamination.

Contact M-Mac Actuators, Inc. by phone at (877) 980-0732; or visit www.mmacactuators.com. Phone MTS Systems Corp., Sensors Div. at (919) 677-0100; or visit www.mtssensors.com.