Resource recovery incinerators help offset the problem of shrinking landfill space by turning trash into energy. In a sense, they recycle the energy contained in municipal waste. Recently they have come under fire from environmentalists because of emissions. Simultaneously controlling several combustion parameters can improve combustion efficiency and reduce emissions. The goal is to extract maximum heat from refuse, which maximizes power generation and burns off most of the residue.

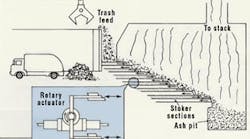

Figure 1. Hydraulic rack-and-pinion rotary actuators drive stoker assembly that boosts performance and reduces emissions of resource recovery incinerator.

Another goal is near-steady-state energy release to maximize steam turbine efficiency and reduce maintenance. The problem is that these goals must be achieved with a refuse supply that has inconsistencies in btu value and moisture content. Accurate control of the combustion process is the key to optimizing modern resource recovery incinerators.

Morse Boulger Inc., a 100-yr-old incinerator and stoker manufacturer with over 3600 ton/day capacity on line in the United States introduced an Electrohydraulic motion-control system that improves combustion efficiency. The system helps an incinerator burn at 1700° to 1900° F, the ideal temperature range for burning refuse. Cooler temperatures prevent undesirable gasses from burning off completely; hotter temperatures can damage firebrick and generate other harmful emissions.

The hydraulic solution

The combustion process involves coordinating over-fire and under-fire air flow, refuse feed rate, and stoker speed in combustion sections of the furnace. Stokers are large grates that agitate refuse in the furnace to promote uniform burning and advance refuse through the furnace by pushing refuse down a series of steps. These moving steps are created by the reciprocating motion of the stokers, Figure 1. Rack-and-pinion rotary actuators move three pairs of stokers back and forth.

In the past, an operator usually had to manually adjust air flow, refuse feed rate, and stoker speed. This required close supervision by an operator, whose knowledge, attention, and experience determined combustion efficiency. Unfortunately, variation in refuse heat and moisture content compounded the problem. As a result, this open-loop, manual process proved inaccurate, burdensome, and inefficient.

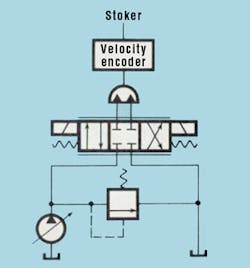

Figure 2. Schematic of proportional electrohydraulic stoker drive.

Morse Boulger uses a closed-loop process control system with sensors that detect variations in refuse btu values and moisture content. To respond to these variations, a programmable logic controller (PLC) sends 4- to 20-mA signals to modulate air flows, refuse feed rate, and speed of individual stoker sections in the combustion section. Speed of each stoker is controlled by a proportional valve that supplies a rotary actuator driving each stoker.

Valve characteristics

An on-board electronics amplifier section of the valve processes the signal. A pulse-width-modulation circuit then proportionally shifts the valve spool to increase or decrease output flow to the rotary actuators driving the stokers. The actuators have 90 (degree sign) of rotation and take 45 sec to 2 min to pivot 90°, depending on demand.

Proportional valves supply the actuators with 1 to 2.5 gpm, Figure 2. Pressures to 750 psi transmit torque to 75,000 lb-in. A variable scan time in the PLC compensates for combustion inconsistencies. Morse Boulger closes the system’s speed control loop with external velocity transducers that monitor the actual speed of the stoker. If stoker speed deviates from command speed, the error is detected and the proportional valve command adjusted accordingly.

Certain characteristics of the proportional valves make them ideal for this application. First, the valves are relatively insensitive to dirt; SAE class #4 filtration common to most industrial hydraulic systems is sufficient. Second, the valves have an internal electronic closed-loop feature that constantly monitors spool position and maintains accurate control. Third, manual overrides allow shifting valves without power during setup or testing. Built-in diagnostic LEDs indicate when a command signal is present at the valve. Moreover, the valves mount on a standard NFPA D03 (formerly D01) subplate pattern, making them fully interchangeable with solenoid valves that had been used previously.

Beneficial results

Use of Electrohydraulic proportional valves in conjunction with a PLC results in consistent, complete incineration of the charge, regardless of the btu value of the refuse, and with little intervention from an operator. The end result is a combustion process that maximized throughput and power generation capability of the plant while reducing smokestack emissions.