Appeared in print as "Diaphragm pump makes for smooth service"

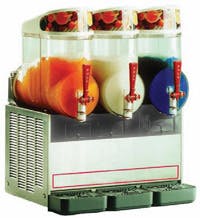

By Catlin Nalley, editorial internThe Flojet series Pulpjet air operated diaphragm pump from ITT Flowjet, Santa Ana, Calif., is designed for dispensing juice and smoothie mixes that contain pulp and other particles. It can pass particles of at least 18 in. (3 mm), and the pump’s smooth flow path allows for liquids containing pulp that would otherwise get caught on moving parts or become emulsified into the finished product. Therefore, it can dispense smoothie mixes (mango, strawberry, and banana), slushies, condiments, as well as acidic condiments such as pizza sauce. “ The pump's uniquely designed, central opening check valve allows soft solids and stringy particles to pass through without the risk of clogging, but it still is capable of high backpressures,” said Peter Wright, Strategic Product Manager at ITT Corp.

The pump is 5.5 in. tall, 4.5 in. wide, and can handle supply pressures to 80 psi. It is rated for liquid flow up to 5 gpm at 90 psi air inlet pressure. Wi th 1 2-in. ports at 2 gpm, it consumes 1.0, 1.3, 1.7, or 2.2 scfm of compressed air at 40, 60, 80, or 100 psi, respectively.

Beverage experience increases efficiency

According to ITT's Rich Occhipinti, the Flojet pump does not leak while at rest, which sets it apart from most other industrial pumps, because leakage often is tolerated in many industrial settings. But because this pump was modeled after the company’s pump normally used in beverage dispensing, where CO2 is used, leakage is absolutely not allowed. “Our patented air distribution system contributes a lot to efficiency, with little friction during movement because it uses ceramic over Delrin rather than the traditional O-ring spool design,” Occhipinti says. “It costs money to run compressors, and as most of the industrial pumps have max 10% usage, this is a big factor.”

A built-in shutoff switch, specifically tuned to highly viscous liquids, automatically turns the pump off when a supply bag becomes empty and restarts when a full bag is connected.

For more information, visit www.flojet.com or call (714) 557-4100.