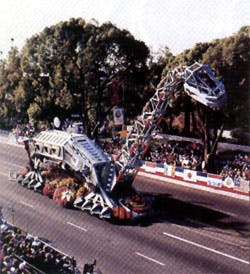

The Sweepstakes Trophy for best float at the 1992 Tournament of Roses Parade was awarded to the entry sponsored by General Motors. Designed as a futuristic, 90-ft-long space-exploration vehicle that resembled a brontosaurus, the winning float carried the motto “Looking Into the Future” and exemplified the parade theme: “Voyages of Discovery.” Parade watchers were fascinated as the brontosaurus’ long neck moved from side to side as well as up and down, and the giant head swooped to within a foot of the crowd.

Animation of the brontosaurus was provided by fluid power and motion control components from Vickers, Inc., Troy, Mich. These included cylinders, pumps, and valves. A total of twelve compact TQ cylinders, ranging in bore size from 2 to 4 in., and in stroke length from 6 to 30 in., drove the horizontal movement of the neck and the rolling motion of the head 458 to either side of center in a medium-pressure circuit. Seven TG cylinders in a higher-pressure circuit provided the neck's vertical motion. These cylinders ranged in bore size from 31/4 to 7 in, with strokes from 24 to 54 in.

Three pumps, connected in tandem configuration to conserve space, supplied hydraulic oil flow to all circuits. Directional control was maintained by a mix of proportional and bang-bang directional control valves. Inside the brontosaurus head, two operators — one for the neck, the second for the head — each maneuvered a pair of joysticks to bring the huge latticework animal to simulated life. A soft-shift enhancement on some of the valves enabled the head to move with a natural- looking flowing motion and to stop without jerking. Cushions in the cylinders also contributed to smooth motion.

Other Vickers components included DGMFN flow controls, sandwiched under the directional valves to regulate the speed of the neck movement, and relief and solenoid valves used on the caster system of the main front suspension. (A third operator on the lower platform drove the float.)

Reliability was a foremost consideration because of the national television audience and the challenging 51/2-mile parade route. Vickers representatives and its local distributor worked closely with GM and the float builder — putting more than 50 hours of testing and fine-tuning into the hydraulic system to make sure everything on the float worked exactly the way it was designed.

John Kostyal, entertainment market specialist in Vickers’ San Francisco office, provided details about this float.