Mobile scissor lifts are used throughout the construction and industrial maintenance industries to carry personnel, tools, and equipment to job sites and then raise them to work on off-theground projects. Hydraulics is integral to their propulsion and lift circuits. As scissor lifts become larger and more sophisticated, their manufacturers are seeking hydraulic systems that combine precise levels of control, reliability, and easy servicing in a compact package.

ne example: Grove Manlift, Shady Grove, Pa., recently introduced a new line of high-reach, high-capacity scissor lifts, the SUPER-MAXX Series, Figure 1, that can reach working heights from 31 to 46 ft, and has platform load capacities from 1500 to 2,000 lb. The line offers combustion engine-powered versions as well as electric-powered models. Front-wheel drive is standard, while 4-wheel drive and 4-wheel steering are options.

Because of the larger size and capacity of the new series, Grove chose proportional control for the hydraulic systems to provide smoother operation of the drive and lift functions. In addition, to keep the hydraulic package compact, they specified an integrated hydraulic circuit in a single manifold for the series.

These decisions provide Grove with a pre-tested hydraulic package that arrives as a single, complete assembly from a single source. The arrangement eliminates much of the plumbing that would be required with separate hydraulic components, and minimizes the number of potential leak points while greatly reducing weight and size. Grove’s customers also benefit from easy troubleshooting and the ability to simply replace screw-in cartridges in the event of a malfunction.

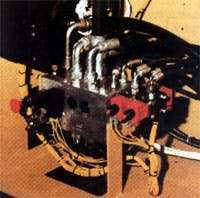

All hydraulic control valves are mounted in or on an aluminum manifold, Figure 2. This integrated circuit contains standard threaded cartridge valves, a specially designed pilot-operated, three-way proportional cartridge valve, and bankable solenoid-operated directional valves bolted to the exterior surface. The cartridge valves provide a series of relief, directional, and flowcontrol functions. The bankable directional valves operate the steering functions. A single bankable valve is used in models with single-axle steering, while dual bankable valves are used for dual-axle steering. The pilot-operated, three-way proportional cartridge valve controls the drive and lift circuits.

The engine-powered scissor lift has a variable-displacement, axial-piston pump, Figure 3, with load-sensing for drive and lift functions. This pump automatically senses hydraulic load and limits torque output to provide cooler, more efficient operation and eliminate potential engine stall-out. A fixed-displacement gear pump supplies the steering circuit.

The electric-powered lifts use a fixed-displacement gear pump to supply all hydraulic functions. On these units, the valve manifold also contains a series of cartridges that divert surplus flow back to tank when only the drive or the lift are operating proportionally at slow, metered speeds.

The manifolds on the engine-powered models incorporate 20 functions on the single-axle steering models, while the 4-wheel steering units include 21 functions. Manifolds on the electric-powered models provide 23 functions in the single-axle steering version and 24 functions in 4-wheel steering models.

As a safety feature, all manifolds incorporate a cartridge-style hand pump, Figure 4, to manually lower the lift in the event of a hydraulic power failure. The hand pump operates a counterbalance valve to slowly bring the work platform down to ground level.

From the operator’s panel, a multiaxis joystick controls both drive and lift functions proportionally for smooth starts and stops. Proportional control also permits inching the platform into position for close-up work. The joystick operates the proportional pilot valve which provides a variable-output pressure signal to the 3-way proportional valve for the drive and lift functions. A toggle switch selects the drive or lift functions. The joystick is also used to control steering. Units with 4- wheel steering have a switch to select front or rear steering.

Chip Knothe, systems application manager, Parker Hannifin, Hydraulic Valve Div., Forest City, N.C., described the lift hydraulics. His company designed and built the manifold, and manufactures the cartridge and bankable valves.