There is much going on in the world of hydraulics, pneumatics and electronics motion systems, from technology introductions and industry advancements to new trends and industry leaders. Each week the Power & Motion team collects some of the latest industry news to help keep our readers up to date on what's happening in the fluid power and electronic motion control sectors as well as the industries they serve.

Emerson Acquires Electric Linear Motion Company

Emerson has acquired Afag Holding AG, a developer of electric linear motion, feeding and handling automation technologies. This acquisition is expected to help expand Emerson's offering of automation solutions and support its long-term growth strategies.

Afag currently serves customers in a range of markets such as battery manufacturing, automotive, packaging, medical, life sciences and electronics. Its electric linear motion technologies will complement those of Emerson as well as its pneumatics portfolio of products.

"As discrete and hybrid customers continue to accelerate electrification across their manufacturing processes, Afag’s technology is ideally suited to provide improved energy efficiency and performance gains," said Ram Krishnan, chief operating officer of Emerson, in the company's press release announcing the acquisition.

READ MORE: What are the Impacts of Industry Consolidation?

NFPA Networking Event to Connect Fluid Power Industry and Future Workforce

The National Fluid Power Association (NFPA) is hosting a Wisconsin Workforce Engagement Group meeting and Fluid Power Club Speed Networking event at the Milwaukee School of Engineering (MSOE) on September 15.

According to NFPA, the Speed Networking portion of the event will allow NFPA members to meet with MSOE engineering student in a roundtable style event where they can walk from table to table meeting members and learning more about their companies and technology developments. Members are encouraged to come prepared with information on open positions, internships and other opportunities to discuss with students.

The Engagement Group meeting will be similar to other Workforce Engagement Group Meetings during which updates and opportunities are shared related to student outreach and recruitment activities. This meeting will have a heavy focus on MSOE's Bachelor of Science in Technical and Business Management program, looking at ways to help bring students into the program to help build future fluid power business leaders.

Further details on this event and how to register can be found on NFPA's website.

STLE Accepting Abstracts for 2024 Annual Meeting

The Society for Tribologists and Lubrication Engineers (STLE) is currently accepting submissions for presentation abstracts for its 2024 annual meeting. Abstracts for oral, student and early career poster presentations are will be accepted through Monday, October 2, 2023.

Industry professionals from around the world working in the tribology and lubrication field are invited to submit their abstracts. The organization is looking for presentations covering the latest technologies related to the more than 20 technical categories set to be addressed at the event such as use of AI and Machine Learning, biotribology, seals, surface engineering and more.

The STLE 78th Annual Meeting & Exhibition is set to take place May 19-23 in Minneapolis, MN.

Watch our interview with STLE president Hong Liang, Ph.D. to learn more about current trends in the tribology and lubrication industry.

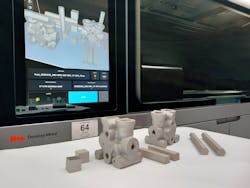

Aidro Receives AM Certification for Metal 3D Printing

Aidro, a Desktop Metal company, recently received AM Manufacturer certification from DNV, a risk management and quality assurance society for the oil & gas and maritime industries, for its binder jetting and laser powder bed fusion printing technologies. The company's facility in Taino, Italy, received the DNV-SE-0568 and DNV-ST-B203 certifications which are used to help provide a standard to which additive manufactured (AM) products are made.

To receive the certifications, DNV conducted an audit of Aidro's facility which included how the company produces and qualifies the fluid power components it manufactures with 3D printing technology. The company's binder jetting and laser powder bed fusion processes received the certification, helping to demonstrate the quality of its products.

“The rigorous process used by DNV will enhance industry confidence in these additive manufacturing methods and continue to support the transition of the demanding energy, oil & gas, and maritime industries toward Additive Manufacturing 2.0. Customers taking the leap into the AM 2.0 future are already realizing incredible benefits, including performance enhancements, lighter weight parts, distributed on-demand manufacturing and digital inventory that reduces the need for physical stock,” said Valeria Tirelli, President and CEO of Aidro, in the press release announcing the company's certification.

READ MORE: Additive Manufacturing Brings Opportunities to Improve Component Design and Production

"We congratulate Aidro for being the world's first in the industry to receive DNV's qualification for Binder Jetting Technology (BJT) at AMC 1 level and AMC 3 level for Laser Beam Powder Bed Fusion technology (PBF-LB). We look forward to continuing close cooperation with Aidro to drive the digitalization shift in manufacturing and providing them and their customers with assurance and confidence in AM products as their use grows across the energy spectrum," said Dr. Sastry Kandukuri, Global Practice Lead on Additive Manufacturing at DNV's Technology Centre in Oslo, Norway.

Aidro uses the Desktop Metal Shop System for printing stainless steel products which aids with the process and ensuring components will meet the requirements of various applications.

The company began working with DNV in 2018 to help draft guidelines the society uses for its standards as the company understands the value AM can bring to various industries as well as the need to ensure the quality of the products manufactured using this technology.

Chinese Mine Deploys 100 Hybrid Autonomous Mine Trucks

EACON, a developer of autonomous mining technology, recently deployed 100 hybrid autonomous mine trucks at a coal mine in China. According to the company, this is the largest fleet of autonomous mine trucks at a single mine in the world to date.

The company began to develop its autonomous technology for open-pit mines in 2018 and expanded into the alternative energy space in 2022. It established a team dedicated to the development of electric power systems and chassis designs. Electrification and automation are viewed as complementary technologies due in part to the increased need for electric components which enable both and the efficiency gains they can bring.

Various EACON technologies are incorporated into the autonomous mine trucks including:

- autonomous driving solution

- plug-in hybrid electric drive system

- intelligent vehicle-wide energy management system

- specialized range extender system for large-tonnage mining trucks

- wire-controlled braking

- fully hydraulic wire-controlled steering.

Normal power demands for the mine trucks is supplied by an auxiliary power unit (APU) while the trucks' batteries are used for transient power requirements such as climbing or acceleration. A regenerative braking system helps to recover energy and keep the battery charged.

To optimize performance and efficiency, the mine trucks feature an intelligent energy management control strategy and thermal management system. EACON states these technologies provide fuel savings up to 30%.

The 90-ton capacity trucks have demonstrated their ability to work on slopes with grades up to 35% and achieve top speeds of 45 km/h, ensuring their performance in various mine conditions.

READ MORE: The Intersection of Electric Drive and Automation Technologies