It is easy for certain sounds, sights, and other ambient environmental conditions of a chemical processing, oil and gas, or other industrial facility to become second nature. The distant hiss of a compressed air line, small droplets beneath steam tubing, or a faint whiff of gas may be so common that it barely registers with plant employees. That does not mean, however, that they should not be addressed.

In fact, these sounds, sights, and smells are indications that something is wrong and could reflect inefficiencies in the fluid system. No matter the severity of the problem, it is important that the leaks be addressed as quickly as possible.

Typically, there are three specific types of leaks:

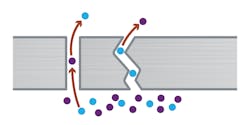

- Real Leak: A leak resulting from the failure of a pressure barrier to contain or isolate a system fluid from the surrounding environment. This occurs due to cracks in the material or gaps between sealing surfaces.

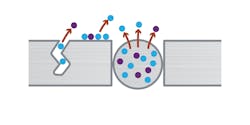

- Virtual Leak: A release of internally trapped fluid into a fluid system due to material outgassing, absorbed or adsorbed fluids, entrapment in crevices, or dead legs.

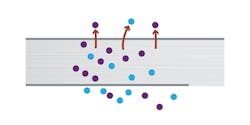

- Permeation: A passage of fluid into, through, and out of a pressure barrier that does not have holes large enough to permit more than a small fraction of the molecules to pass through any one hole.

Whether the leaks are real, virtual, or permeating, they can often go undetected. Leaks frequently happen at connection points in the fluid system and may be a simple nuisance—but they can also cost money and provide potential hazards for employees and the environment.

READ MORE: Stop High-Pressure Leaks with Flanges

As regulators strengthen what constitutes an emissions violation and investors start taking environmental concerns more seriously, operators are increasingly required to reduce the possibility of even small leaks to nearly zero. It is crucial to understand the different leaks that may occur in industrial facilities and have strategies in place to limit them as much as possible (Figures 1A to 1C).

Environmental Emissions

The term “environmental emissions” refers to an uncontrolled leak of gases into the air of a facility. Benzene, methane, and ethanol are common gases that can pose potential ozone creation and damage air quality in the plant if they leak from the fluid system.

A good example of how governments and corporations are beginning to target these types of emissions is found in the Greenhouse Gas Protocol’s definition of Scope 1, Scope 2, and Scope 3 emissions.

- Scope 1 emissions represent direct emissions from a company’s operational activities, including emissions from burning fuel and from direct leaks of greenhouse gases into the environment

- Scope 2 emissions are generated from a company’s purchase of electricity, steam, heat, and cooling

- Scope 3 emissions include all indirect emissions not covered by Scope 2

The Greenhouse Gas Protocol (GHGP) notes that companies can identify opportunities to bolster their bottom line, reduce risk, and find new competitive advantages by actively reducing their emissions. For process-driven facilities, seeking out and addressing any form of carbon emissions via leaking process equipment can lead to significant operational benefits (Figure 2).

Costly Leaks

In addition to industrial carbon emissions, other nonhazardous leaks can happen in industrial facilities that can still cost facilities significantly if they are not diagnosed and fixed.

Steam is an ideal example of a nonhazardous leak that’s used for multiple production purposes throughout industrial facilities and costs both money and energy to produce and use. First, water must be purified before turning into steam and then it must be transported from the steam generator to the point of use. Unintentional leaks in steam systems are a common problem that can increase the costs of maintaining facilities at peak performance.

In addition to steam, compressed air system leaks may also not be an immediate threat but may result in significant loss of revenue. For example, poorly performing compressed air systems can put additional strain on the compressors, causing them to fail before they should. Fixing compressed air leaks may mean facilities will not have to install auxiliary compressors, saving money in the process.

Identifying and Fixing Common Leak Culprits

In most cases, leaks occur at fitting and valve connections and may go undetected if they are not regularly monitored.

In the case of fittings, improper installation is most often the culprit for poor performance. However, certain types of fittings are more prone to leaks than others. For example, NPT threaded fittings—a common type of small-bore fittings—have been found to leak more frequently than certain types of mechanical grip tube fittings, which create longer lines of sealing contact between their ferrules and the tubing. By selecting and specifying higher-performance tube fittings throughout applicable fluid systems, operators can be more certain of leak-tight performance.

READ MORE: The Basics of Small-Bore Fittings

Meanwhile, valves offer fluids more opportunities to escape the system, making the selection of high-quality components even more important. Valves are made up of multiple individual parts, including a stem, seal, handle, and more, each of which may represent a potential path for fluids to escape. Valves are also dynamic—frequent opening and closing can cause wear to some parts, which over time can lead to greater leak potential.

Proactive Leak Detection

Partnering with the right supplier who can supply leak-tight components is crucial. With the right expertise, suppliers may also be able to advise on system design that includes fewer potential leak points. Additionally, they may be able to help identify and address leaks through a leak detection service, which can help systems perform more reliably and efficiently and reduce overall energy consumption and emissions during regular facility operation.

Leaks cost money, so each day they are undetected or unaddressed, it lowers facilities’ profit margins. That is why it is important to monitor potential leak sites aggressively and fix them as quickly as possible. Using high-quality components produced by a reputable supplier can help eliminate unnecessary leaks and lead facilities ever closer to becoming leak-free operations.

This article was written and contributed by Randy Rieken, Market Manager, Swagelok Company.

An original version of this article appeared on the Swagelok Reference Point blog: https://www.swagelok.com/en/blog/reduce-fluid-system-leaks-fugitive-emissions#.