This file type includes high-resolution graphics and schematics when applicable.

A fence contractor had a hydraulic attachment for his front-end loader that hammered fence posts into the ground. He would only get about two to three months of operation from the system before the hammer’s pressure-compensated pump would fail. The pump manufacturer denied warranty claims, citing “lack of lubrication” as the cause of the failure.

The contractor asked the pump manufacturer what evidence led them to conclude that the failure was due to lack of lubrication. He told them he was using the recommended oil, changed the return filters whenever the dirt indicator (âP) gauge approached the yellow zone, and claimed the gauge never reached the red zone. The pump was driven off a gas engine that idled at 3600 rpm and about 2200 rpm under load.

They told him the piston barrel face was “welded” to the front plate it rotated against. The front cover of the pump, a Vickers PVB series, also acted as the pressure plate the barrel spins against.

Any idea what was causing the premature pump failures?

Find the Solution

Think you know the answer to this month’s problem?

Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by January 5, 2016, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Shailendra Chaurasiya, who won December’s Troubleshooting Challenge by having his answer drawn at random from those who correctly solved the problem. A $50 gift card was sent to him.

Solution to the Previous Troubleshooting Challenge: Cylinder Running Slow

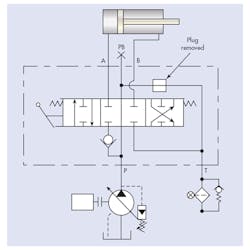

A progressive die press was designed to form shell casings for use in military tanks. After the machine performed well during test runs, with the customer observing the results, it was disassembled before being shipped overseas for operation.

After it was reassembled and running, it started to cycle slower than the designed cycle time. Adjusting the hydraulic system’s counterbalance valve did not help.

The operator noted that the tank line of the relief valve was not warm to the touch. A warm or hot tank line would indicate that the relief valve was leaking. The operator also installed a flow meter on the main pump’s case drain, but flow was well within the normal range.

The slow cycling press had a directional valve that required 65 to 75 psi of pressure to fully shift. The springs on both ends of the spool needed to be fully shifted to pass the rated flow. The 65-psi pilot pressure relief spring was discovered to be broken, so the system was only developing about half the pressure needed to fully shift the valve. The spool was partially shifting, acting like a flow control. Replacing the spring or the valve itself would solve the problem.